Aerospace NDT

Aerospace NDT (Non Destructive Testing), and in specific ultrasonic inspection, are aimed to detect and size defects in aerospace materials or components that could be detrimental to mission performance and safety. Advancements of ultrasonic technologies are enhancing the accuracy, speed, and cost effectiveness of inspection of such components.

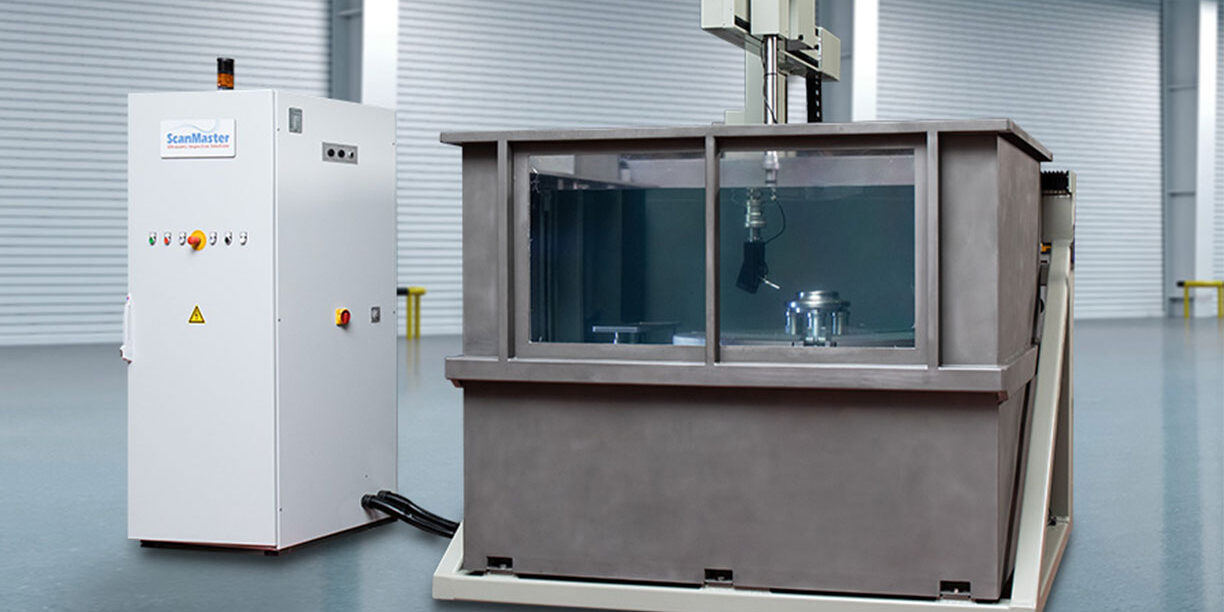

ScanMaster has consolidated its rich experience and know-how to deliver state-of-the-art automated ultrasonic immersion, squirter and contact systems, which are used in aerospace non-destructive testing for accurate and reliable inspection of a variety of components and assure a high inspection throughput.

Approved by the world’s leading manufacturers in the aerospace industry, including Airbus, Boeing, General Electric, Pratt & Whitney, Rolls-Royce, Snecma, MTU and others, ScanMaster’s rugged and reliable systems are designed for multi-shift operation in industrial environments. High-accuracy scanning mechanics, exceptional performance of ultrasonic electronics, high speed data acquisition and processing provide full detection and evaluation of internal defects at high productivity.

In addition to a broad line of standard scanners, ScanMaster provides upgrades of existing equipment and customized systems complying with customers’ specific requirements.

Application-specific systems for aerospace non-destructive testing include:

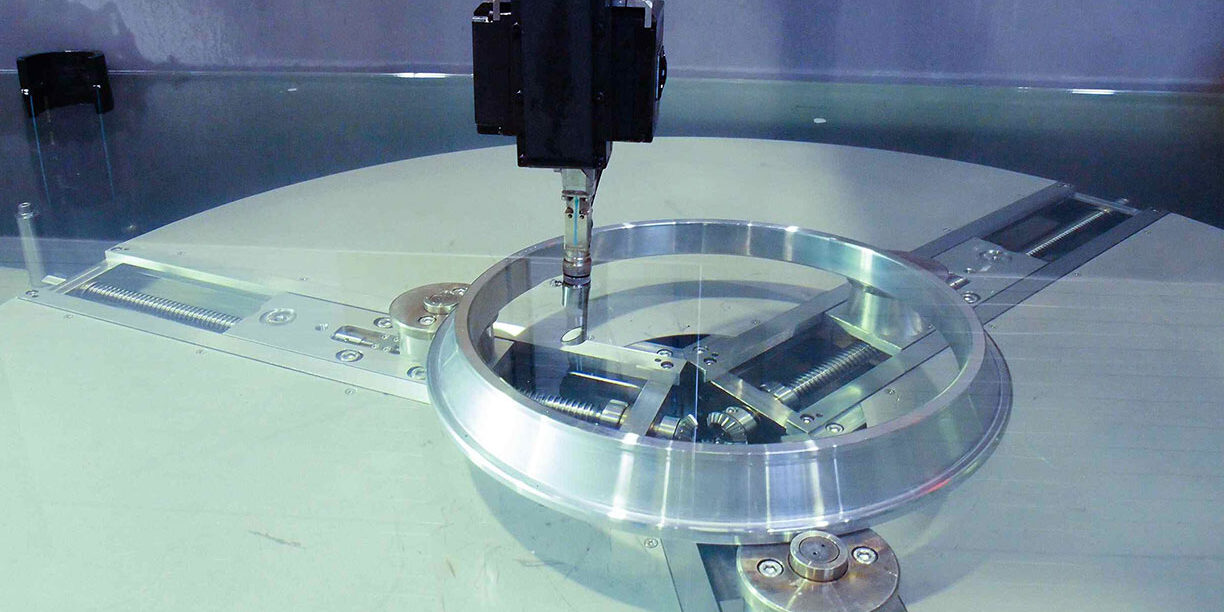

Jet Engine Components

Immersion systems for inspection of disks, blades, vanes, spools and shafts. The 1000 Gates advanced algorithm for automatic evaluation of scan results of jet engine discs can be incorporated in such systems.

Ultrasonic Immersion Systems

Aerospace NDT (Non Destructive Testing), and in specific ultrasonic inspection, are aimed to detect and size defects in aerospace parts and structures that could

Jet Engine Components

Immersion systems for inspection of disks, blades, vanes, spools and shafts. The 1000 Gates advanced algorithm for automatic evaluation of scan results of jet engine discs can be incorporated in such systems.

Ultrasonic Immersion Systems

Aerospace NDT (Non Destructive Testing), and in specific ultrasonic inspection, are aimed to detect and size defects in aerospace parts and structures that could

Aero Structure Components

Large squirter and immersion systems for inspection of aero-structures (metallic and composite parts).

Ultrasonic Immersion Systems

Ultrasonic Inspection of Composites

Billets and Bars

Immersion systems for inspection of bars and billets using conventional and phased array transducers.

Aluminium and Titanium Plates

Integrated systems providing a complete solution for testing and handling of aerospace-quality aluminium and titanium alloy plate

Ultrasonic Bearing Inspection

Immersion systems for high performance inspection of bearings used in a variety of applications, including railways and power generation.

Customized Systems

Special purpose machines, tailored to customer specific requirements.

Aero Structure Components

Large squirter and immersion systems for inspection of aero-structures (metallic and composite parts).

Ultrasonic Immersion Systems

Ultrasonic Inspection of Composites

Billets and Bars

Immersion systems for inspection of bars and billets using conventional and phased array transducers.

Aluminium and Titanium Plates

Integrated systems providing a complete solution for testing and handling of aerospace-quality aluminium and titanium alloy plate

Ultrasonic Bearing Inspection

Immersion systems for high performance inspection of bearings used in a variety of applications, including railways and power generation.

Customized Systems

Special purpose machines, tailored to customer specific requirements.