Pipe & Tube

Today, steel pipes and tubes are used for stringent applications such as the transportation of oil and gas. In such crucial environments, pipe integrity is of paramount importance as defects or flaws could have disastrous consequences.

In a highly competitive and dynamic market, meeting the quality demands of both buyers and industry standards is essential to the success of pipe manufacturers. With the demand for high throughput, pipe mills work three shifts to achieve production capacities of 90% or more, thus requiring fast, robust and cost efficient testing systems. ScanMaster meets these requirements seamlessly. For nearly 3 decades, we have provided manufacturers around the world with a portfolio of leading-edge, cost effective ultrasonic inspection solutions and software products that ensure the highest levels of quality, precision and reliability while boosting productivity.

Designed for continuous heavy duty operation in multi-shift settings while operating in harsh, demanding, industrial environments, our AS200 product line offers:

- In-situ solutions for the inspection of the pipe raw material before pipe forming

- Inspection of the pipe both in-line, as part of the pipe welding line, and off-line for final pipe testing.

- Robust solutions and flexible UT configurations supporting a variety of pipe production technologies.

- Intuitive and easy-to-use software providing accurate and detailed results while eliminating false indications, and allowing fast, uninterrupted production throughput.

Pipe Testing: AS-200 Applications

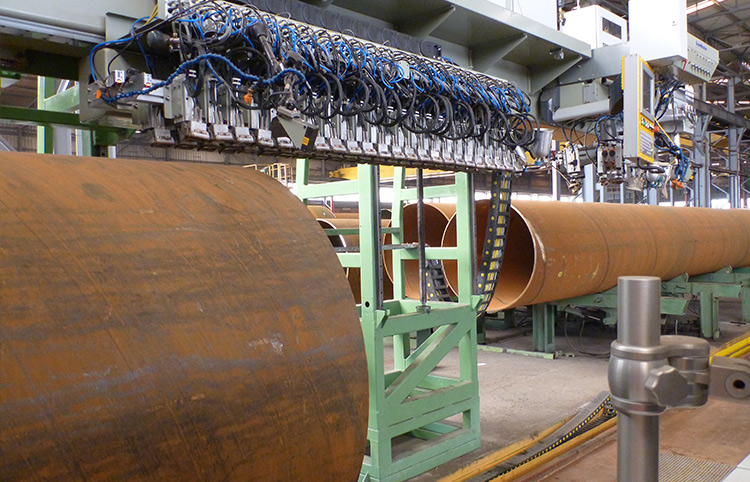

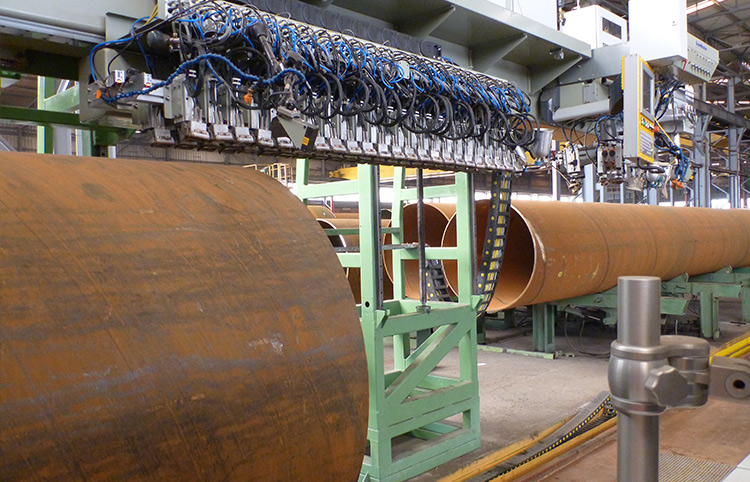

Helical SAW Pipes

ScanMaster offers on-line and Off-line systems configurations

for inspection of Spiral Submerged Arc Welded (SAW) pipe after

welding or after the hydrostatic test.

The systems have modular inspection heads supporting different UT configurations, and can be set up using a variety of ultrasonic configurations, according to the specific inspection requirements.

Off-line systems can be offered with full-body inspection module for detection of delaminations in the pipe body.

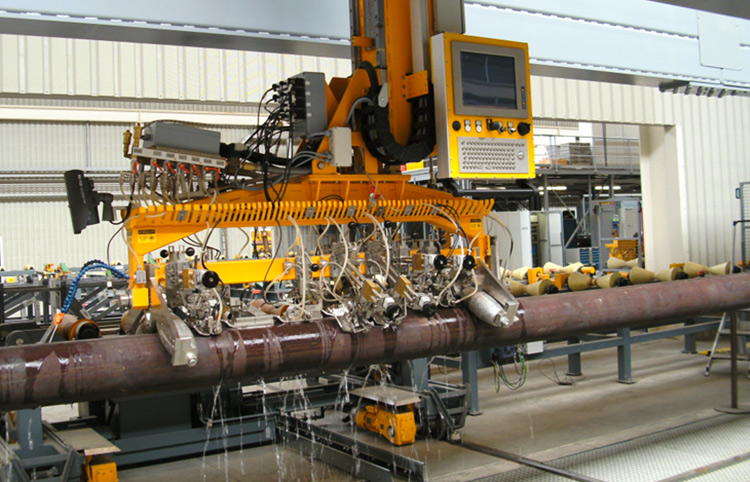

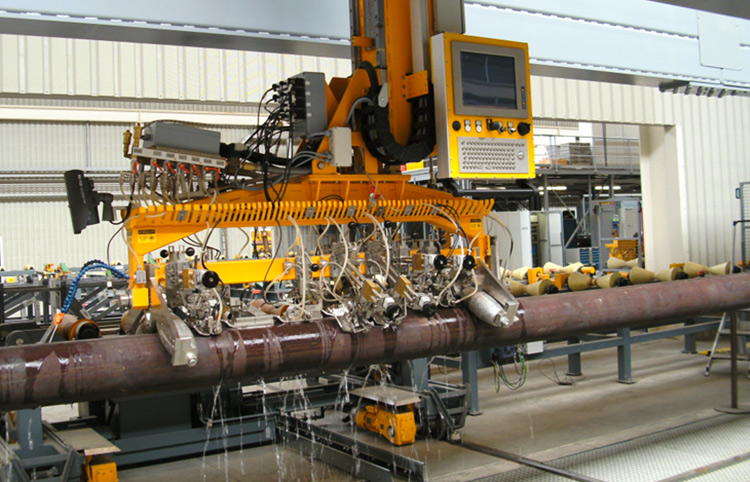

Longitudinal SAW Pipes

ScanMaster offers on-line and off-line systems configurations

for inspection of Longitudinal Submerged Arc Welded (LSAW)

pipe before or after the hydrostatic test.

The systems have modular inspection heads supporting different UT configurations including PA, and can be set up using a variety of ultrasonic configurations, according to the specific inspection requirements.

ERW Pipes

The AS200E System inspects Electro Resistance Welded Pipe (ERW), including weld and HAZ inspection. Systems may be in either online or offline configurations. A variety of ultrasonic configurations according to inspection requirements and site conditions are available.

Both static and moving inspection head configurations are available to accommodate different site conditions and throughput requirements. Full-body inspection systems for detection of delaminations in the pipe body are also available for off-line inspection with different pipe conveying configurations.

Special Pipes

Different inspection configurations to accommodate specific customer's requests.

Pipe Testing: AS-200 Applications

Helical SAW Pipes

ScanMaster offers on-line and Off-line systems configurations

for inspection of Spiral Submerged Arc Welded (SAW) pipe after

the welding or after the hydrostatic test.

The systems have modular inspection heads supporting different UT configurations, and can be set up using a variety of ultrasonic configurations, according to the specific inspection requirements.

Off-line systems can be offered with full-body inspection module for detection of delaminations in the pipe body.

Longitudinal SAW Pipes

ScanMaster offers on-line and off-line systems configurations

for inspection of Longitudinal Submerged Arc Welded (LSAW)

pipe before or after the hydrostatic test.

The systems have modular inspection heads supporting different UT configurations including PA, and can be set up using a variety of ultrasonic configurations, according to the specific inspection requirements.

ERW Pipes

The AS200E System inspects Electro Resistance Welded Pipe (ERW), including weld and HAZ inspection. Systems may be in either online or offline configurations. A variety of ultrasonic configurations according to inspection requirements and site conditions are available.

Both static and moving inspection head configurations are available to accommodate different site conditions and throughput requirements. Full-body inspection systems for detection of delaminations in the pipe body are also available for off-line inspection with different pipe conveying configurations.

Special Pipes

Different inspection configurations to accommodate specific customer's requests.