Ultrasonic Immersion Testing Systems

ScanMaster’s ultrasonic immersion testing systems are designed for high throughput and multi-shift operation in both industrial and lab environments. These fully integrated systems provide various scanning configurations and incorporate conventional and phased array ultrasonic technologies to support diverse applications, from inspection of engine disks and HPT (High Pressure Turbine) spools to scanning of bars, shafts, billets and plates.

Our automated ultrasonic testing (AUT) systems are approved for use in both production halls and aviation MROs by all major manufacturers, including GE Aviation, RR engines, P&W and others.

All of ScanMaster’s immersion tank systems feature high accuracy multi-axis scanning frames to enable testing of complex parts, and include a multi-channel ultrasonic instrument with exceptional performance.

Together with a comprehensive set of software modules, this versatile series of systems provides customers with the best price performance solutions.

Ultrasonic Immersion Testing: Systems Gallery

Features and Benefits

- Powerful teach-in and scanning software enabling inspection of complex 3D parts

- Support of offline part programming through CAD import of part models

- A, B and C-scan data processing and analysis toolkit featuring a rich library of tools for analysis and evaluation of scan results

- 1000 Gates, an advanced algorithm for automatic evaluation of jet engine disc scan results

- Comprehensive inspection reports with standard and customized versions

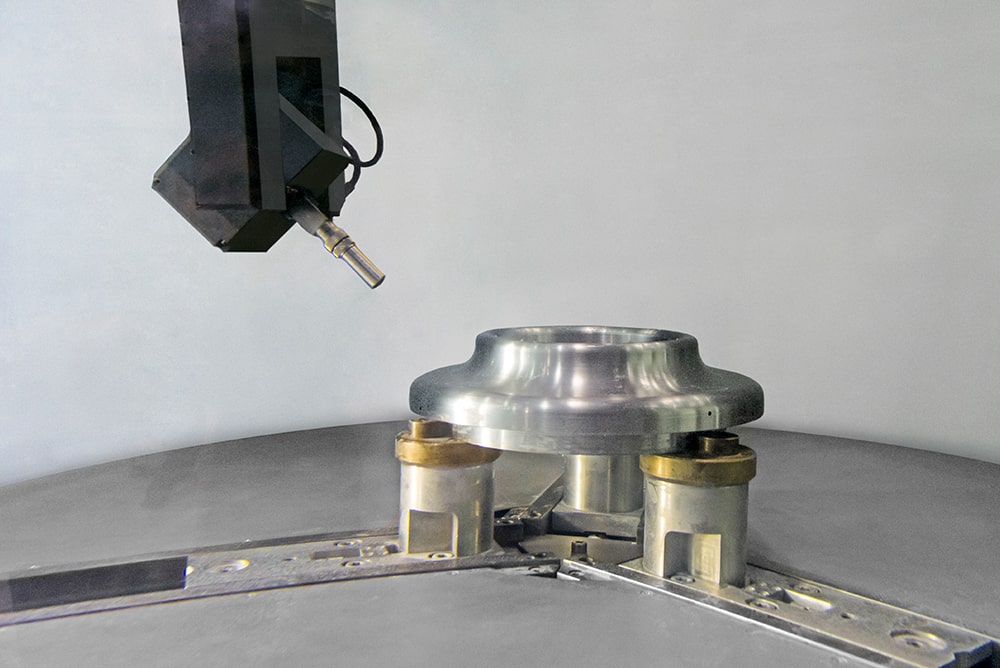

- High-resolution, gimbal-gimbal probe manipulator with protective electro-mechanical breakaway mechanism

- Automation of major functions, promoting efficiency and reducing operator errors

- Specialized toolkit for jet engine spool inspections

Optional Modules

- Continuous motion or two-position motorized lifting device for easy loading and unloading

- Motorized chucking for quick part clamping

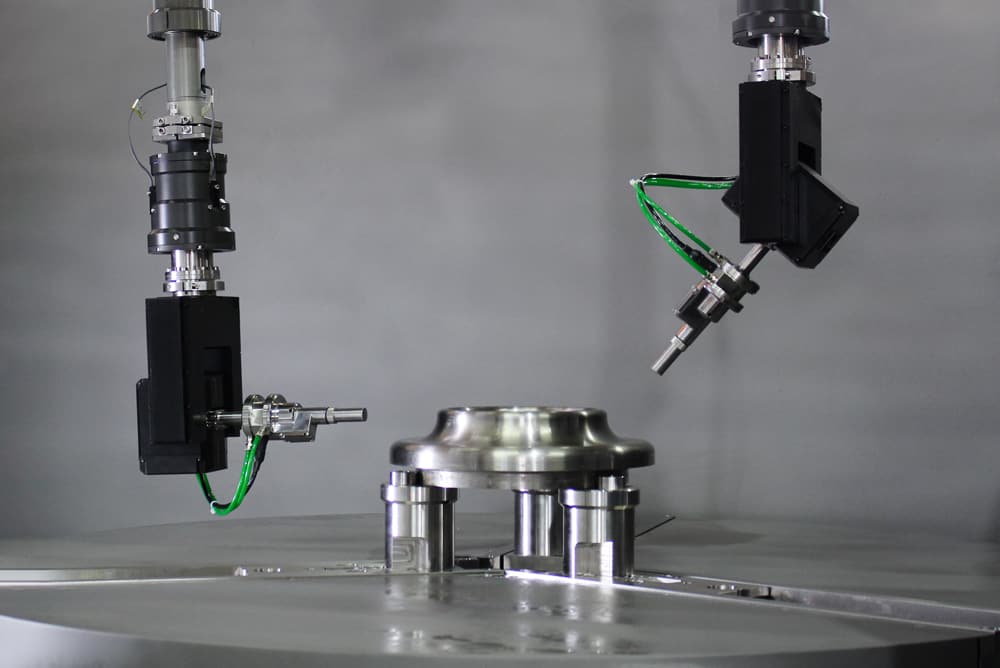

- Application-tailored multi-transducer probe holder

- Loading/unloading industrial robot interface for fully automated inspection

Features and Benefits

- Powerful teach-in and scanning software enabling inspection of complex 3D parts

- Support of offline part programming through CAD import of part models

- A, B and C-scan data processing and analysis toolkit featuring a rich library of tools for analysis and evaluation of scan results

- 1000 Gates, an advanced algorithm for automatic evaluation of jet engine disc scan results

- Comprehensive inspection reports with standard and customized versions

- High-resolution, gimbal-gimbal probe manipulator with protective electro-mechanical breakaway mechanism

- Automation of major functions, promoting efficiency and reducing operator errors

- Specialized toolkit for jet engine spool inspections

Optional Modules

- Continuous motion or two-position motorized lifting device for easy loading and unloading

- Motorized chucking for quick part clamping

- Application-tailored multi-transducer probe holder

- Loading/unloading industrial robot interface for fully automated inspection

SYSTEM SOFTWARE

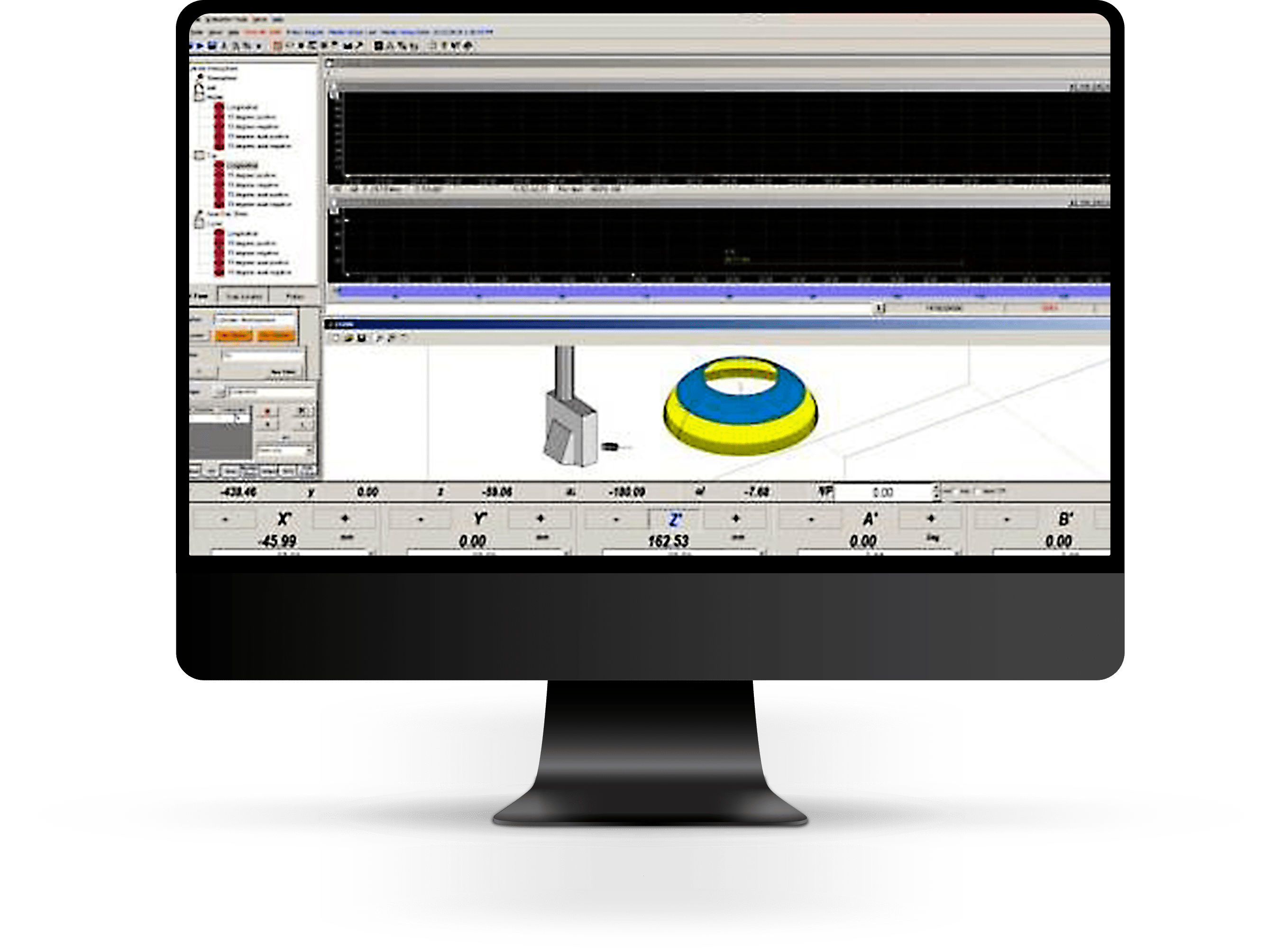

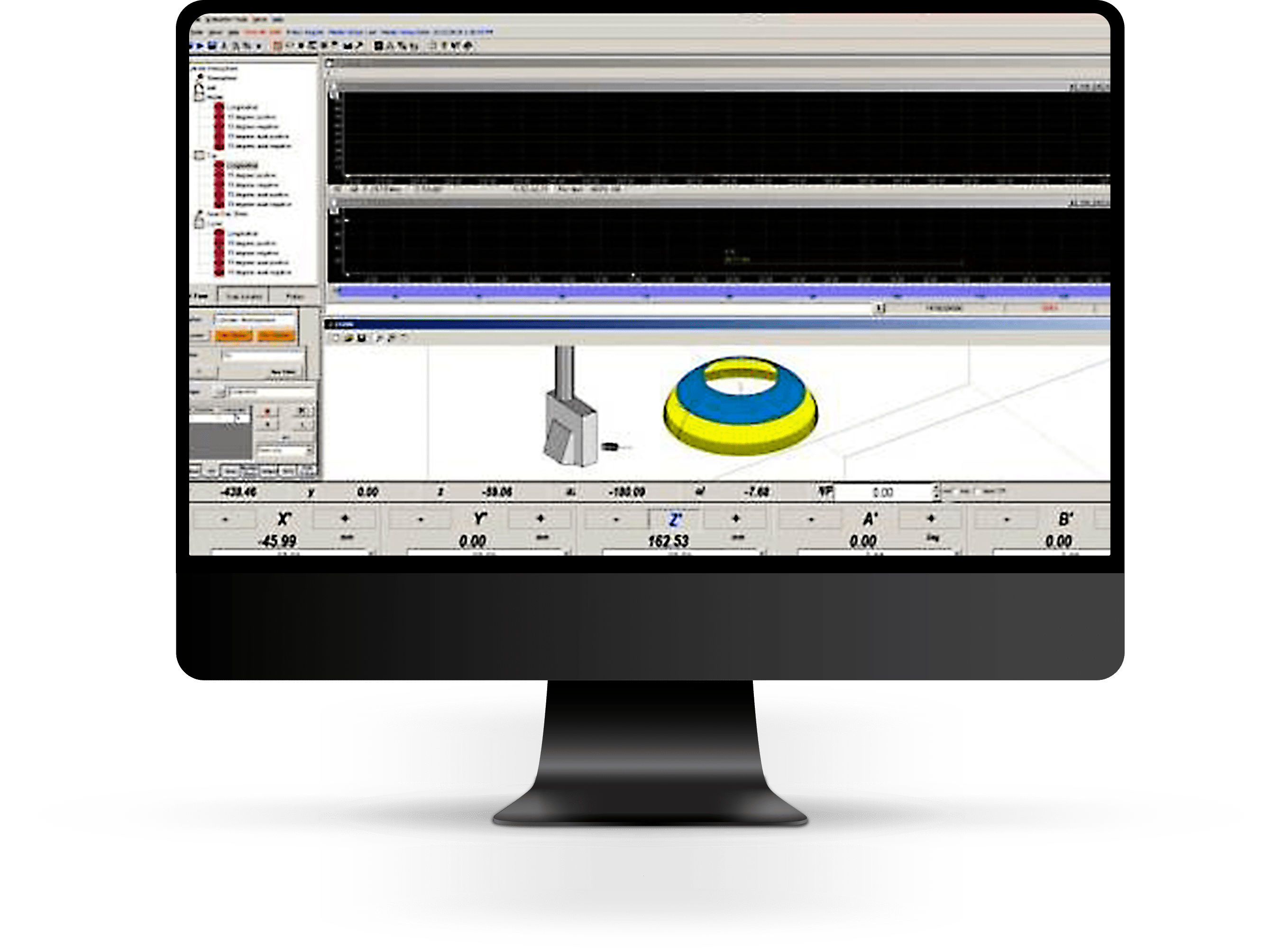

C-Scan Inspector (CSI)

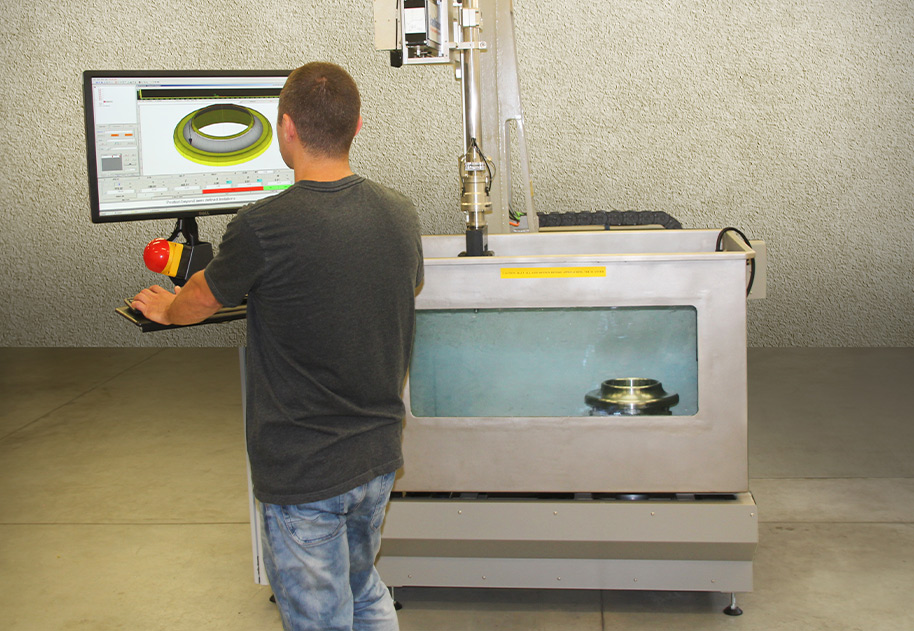

ScanMaster’s CSI software, provides sophisticated yet intuitive tools for system control.

The software enables programming of part geometry, ultrasonic instrument parameters, scan parameters, scan plan sequences and data collection parameters. The software has a single integrated display for control of motion axes, the ultrasonic instrument, Teach-in, scanning and data processing.

The display includes on-line presentation of A, B and C-scans, as well as a 3-D display of part and transducer advancement during scans. The CSI software features an image-processing package that includes a set of standard reports. Customized reports can also be supplied. This package can also operate on off-line stations.

SYSTEM SOFTWARE

C-Scan Inspector (CSI)

ScanMaster’s CSI software, provides sophisticated yet intuitive tools for system control.

The software enables programming of part geometry, ultrasonic instrument parameters, scan parameters, scan plan sequences and data collection parameters. The software has a single integrated display for control of motion axes, the ultrasonic instrument, Teach-in, scanning and data processing.

The display includes on-line presentation of A, B and C-scans, as well as a 3-D display of part and transducer advancement during scans. The CSI software features an image-processing package that includes a set of standard reports. Customized reports can also be supplied. This package can also operate on off-line stations.

Our Ultrasonic Immersion Testing Systems

Our Ultrasonic Immersion Testing Systems

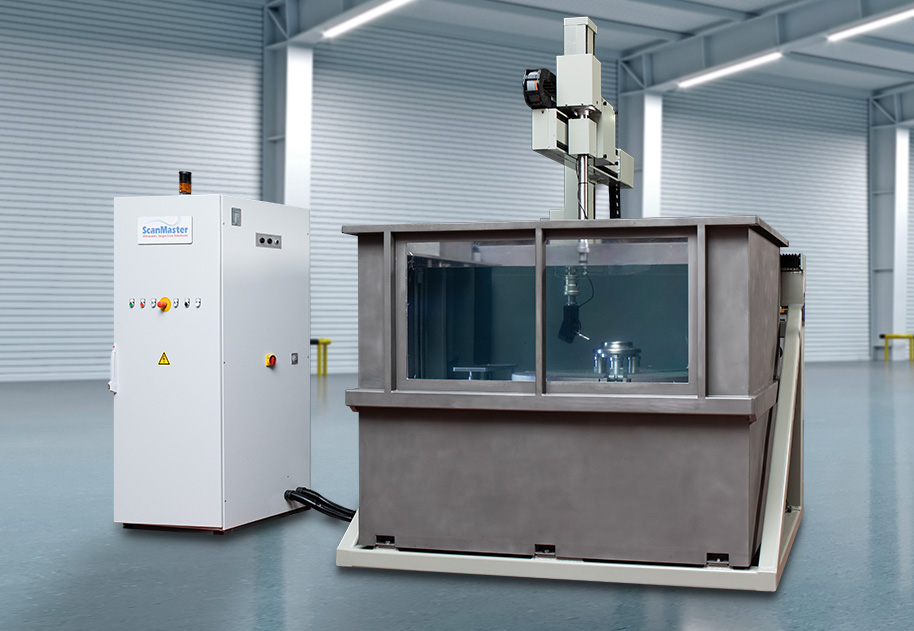

LS-200 Series

Industrial Ultrasonic Scanning System

The LS-200 Series industrial scanners are C-scan ultrasonic testing systems whose unique robotic design combines precision scanning motion with exceptionally smooth and simple part loading and unloading.

Each system includes an integrated usc-100 ultrasonic instrument with a search-tube mounted RPP square wave pulser preamplifier for high sensitivity and enhanced SNR, precision servo motion control and ScanMaster CSI software for part set-up, scanning, inspection analysis and data archiving.

The following scanning platforms are available:

- LS-200S - (X, Y, Z) Maximum motion envelope of 1200 x 600 x 600mm (48" x 24"x 24") with part turntables up to 600mm (24") in diameter.

- LS-200L/LP-1200 - (X, Y, Z) Maximum motion envelope of 1400 x 920 x 1000mm (55" x 36" x 40"), with part turntables up to 1000mm (40") in diameter. A motorized lift platform or two-tiered leveling are available as optional features.

- LS-200LP-1500 - (X, Y, Z) Maximum motion envelope of 1400 x 900 x 1000mm (55" x 36" x 40"), with part turntables up to 1200mm (48") in diameter.

- LS-200LP-WSS model – Approved by GE Aviation for inspection of CFM56-5 ,7 HPT (High Pressure Turbine) & Rotor disc

The LS-200 cantilever configuration can also be provided as an ultrasonic testing solution for bars and billets.

LS-200 PA

An Integrated Phased Array and Conventional Ultrasonic Scanner

Engine disks are important components of turbine based jet engines. However, the stringent requirements of their ultrasonic inspection standards take a significant toll on manufacturing time. One way of reducing inspection time is implementing the phased array ultrasonic inspection technique as part of the inspection plan.

ScanMaster offer's the LS-200 PA, a fully integrated phased array and conventional UT based immersion scanner for inspection of engine disks. The LS-200 PA system significantly increases inspection productivity while maintaining highest detection and evaluation capabilities.

LS-200 PA

An Integrated Phased Array and Conventional Ultrasonic Scanner

Engine disks are important components of turbine based jet engines. However, the stringent requirements of their ultrasonic inspection standards take a significant toll on manufacturing time. One way of reducing inspection time is implementing the phased array ultrasonic inspection technique as part of the inspection plan.

ScanMaster offer's the LS-200 PA, a fully integrated phased array and conventional UT based immersion scanner for inspection of engine disks. The LS-200 PA system significantly increases inspection productivity while maintaining highest detection and evaluation capabilities.

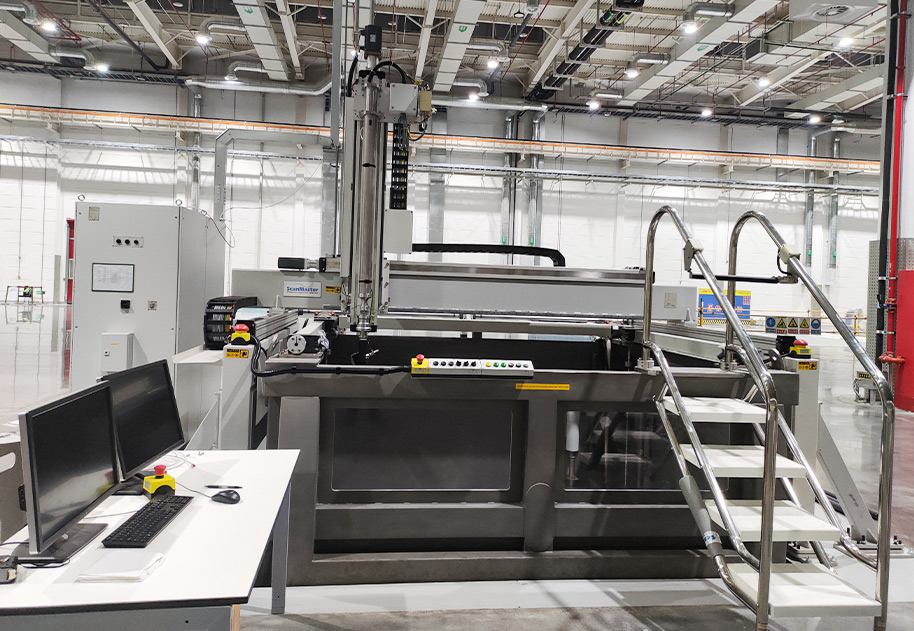

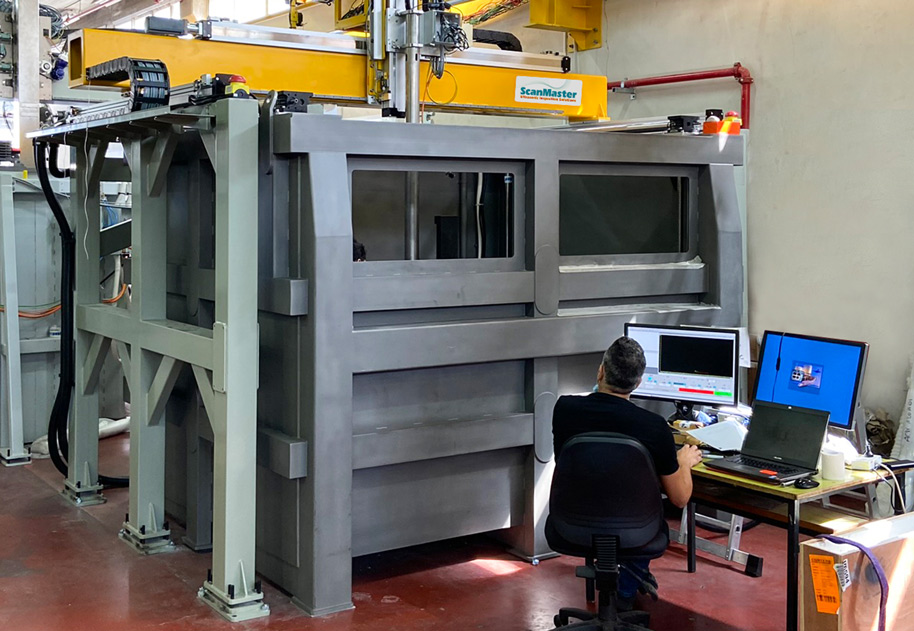

LS-500 Series

Industrial Ultrasonic Scanning System

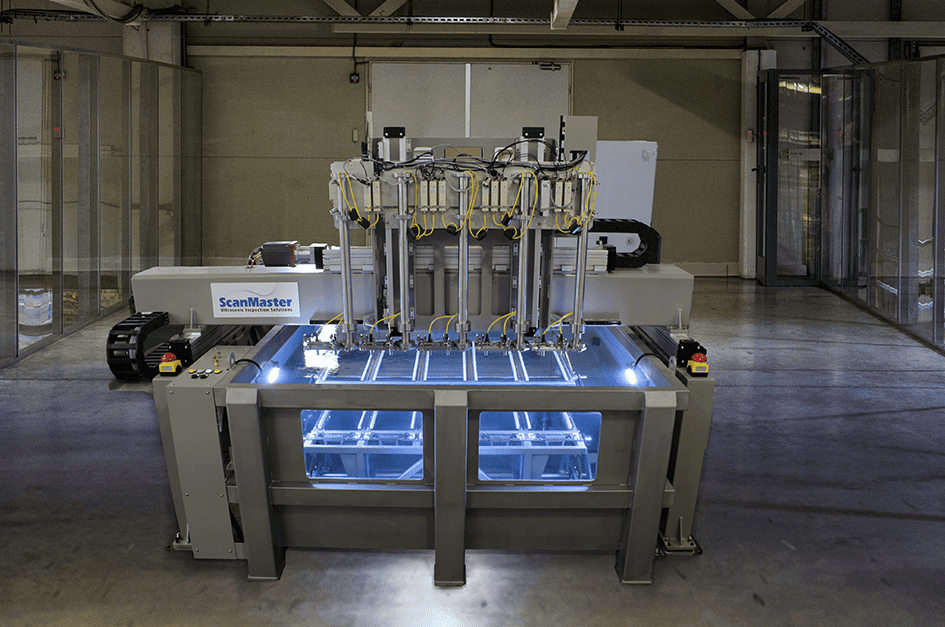

The LS-500 series industrial scanners are C-scan inspection systems whose modular design enables a range of system dimensions according to scanning requirements, with no need for customized designs. The rugged modular design of the bridge-mounted search tube ensures high-speed inspection with tight tolerance limits for accuracy, repeatability and resolution.

The LS-500 series also support ultrasonic phased-array testing.

The standard LS-500-1000 configuration consists of a motion envelope of 1,000 x 600 x 700mm (40" x 24"x 28") with part turntables up to 600mm (24") in diameter.

The LS-500 configuration can also be utilized for ultrasonic testing solutions for bars and billets.

DS-200i Series

Industrial Ultrasonic Scanning System

The new generation of DS-200i scanners provide a cost-effective C-scan inspection solution with a superior design. These fully integrated systems include ultrasonic electronics, scanning mechanics, axes motion control, data acquisition and processing software.

Typical applications for the DS-200i include:

- Large discs and spools of aero-engines

- Rings of large bearing such as wind turbine pitch bearings

- Flat or complex non-rotational parts

Tank in pit configuration

Tank on floor configuration

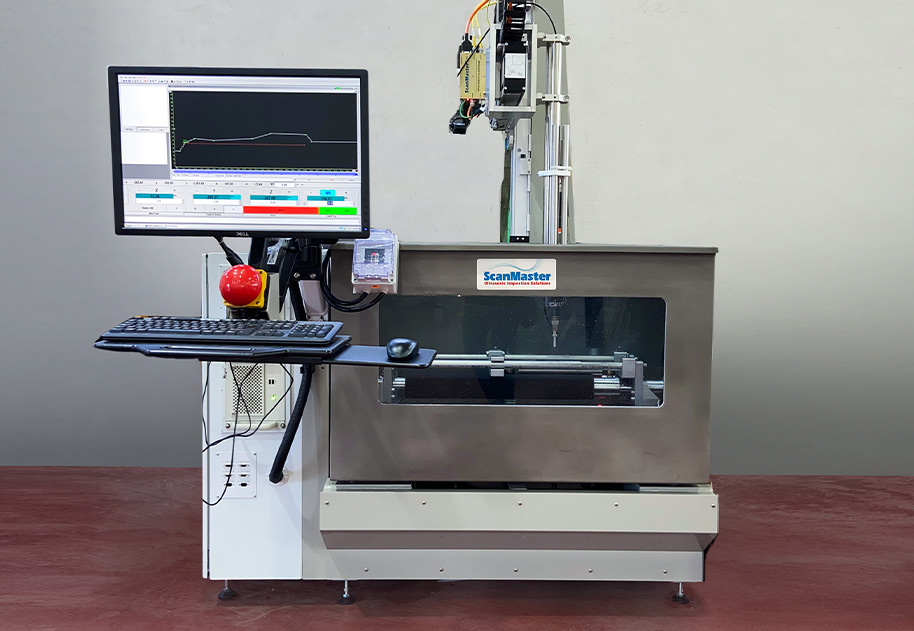

LS-50 Series

Compact immersion scanner- suitable for manufacturing sites, metallurgical labs and research institutes.

The LS-50 is a compact, fully integrated ultrasonic immersion testing system providing an optimal cost-effective solution for inspection of discs, bearing rings, bars, metallurgical samples, monolithic composites parts and more. Although small, LS-50 scanners are complete systems containing UT electronics, mechanics, motion control and software, all designed, manufactured and integrated by ScanMaster. The LS50 includes all the standard features of the CSI application, ScanMaster's well-known inspection software package.

The standard LS-50TT configuration consists of a motion envelope of 750 x 400 x 450mm (30" x 16"x 18") with part turntables up to 400mm (16") in diameter.

LS-50 immersion testing systems can support both turntable and bar rotator:

The LS-50BR

The LS-50TT

Standard Immersion Scanners Configurations

| Product | Motion Envelope Linear Axes |

Manipulator | Max. Part Diameter mm (inch) |

Turntable Capacity kg (lbs) | Water Height mm (inch) |

||

| X mm (inch) | Y mm (inch) | Z mm (inch) | A B

deg deg |

||||

| LS-50 Series | |||||||

| LS-50(**) | 750 (30) | 400 (16) | 450 (18) | ±38 ±112 | 400 (16) | 80 (176) | 300 (12) |

| LS-500 Series | |||||||

| LS-500-1000 | 1,000 (40) | 600 (24) | 700 (28) | ±38 ±112 | 600 (24) | 200 (440) | 430 (17) |

| LS-200 Series | |||||||

| LS-200s | 1,200 (48) | 600 (24) | 600 (24) | ±38 ±112 | 600 (24) | 200 (440) | 450 (18) |

| LS-200L-1200 | 1770 (69) | 920 (36) | 1,000 (40) | ±38 ±112 | 1,200 (48) | 1,000 (2,200) | 820 (32) |

| LS-200LP-1200(*) | 1,400 (55) | 920 (36) | 1,000 (40) | ±38 ±112 | 1,200 (48) | 1,000 (2,200) | 780 (30) |

| LS-200LP-1500 | 1,680 (66) | 1,100 (43) | 1,000 (40) | ±38 ±112 | 1,500 (59) | 1,000 (2,200) | 740 (29) |

| DS-200 Series | |||||||

| DS-200i-1800 | 2,000 (78) | 1,500 (59) | 1,300 (51) | ±38 ±112 | 1,800 (70) | 1,500 (3,300) | 1,200 (48) |

| DS-200i-2000 | 2,000 (78) | 1,800 (70) | 1,300 (51) | ±38 ±112 | 2,000 (78) | 2,000 (4,400) | 1,200 (48) |

(*) LS-200LP-WSS model – Approved by GE Aviation for inspection of CFM56-5 ,7 HPT (High Pressure Turbine) Rotor disc

(**) For bar rotator configuration please reffer to the LS-50 brochure

What is ultrasonic immersion testing?

Ultrasonic immersion testing is an effective means of identifying small defects and material irregularities with a high Probability of Detection (POD). This testing method provides accurate sizing and improved detection of sub-surface defects (improved NSR – Near Surface Resolution). Testing results can be easily viewed in part inspection reports.

Ultrasonic immersion testing is done with the part submerged in an inspection tank, where the water acts as a coupling medium. The ultrasonic probe (transducer) is connected to a probe manipulator (usually supporting two rotating axes) that is part of a cartesian or angular multi-axis scanner. The probe is then moved in a pre-defined trajectory over the part surface, creating a mesh of points (pixels) on which the UT data is retrieved.

The ultrasonic wave, induced by the probe, travels through the water and into the part. Once it penetrates the part, any defects, flaws or inclusions will reflect the ultrasonic wave within the material back to the probe. The time required for the wave to return to the transducer (ToF = Time of Flight) and the associated amplitude can be recorded at any given data point (pixel).

Data acquired during inspection can be viewed (and recalled) as A-Scan (per pixel), B-Scan, C-scan and D-scan images. These images can be analyzed using appropriate image processing tools to gather required information about the part’s integrity.

Immersion testing has several advantages. First, water allows better quality of coupling than that provided by contact inspection, resulting in improved near surface resolution. In addition, use of a computerized multi-axis scanner enables better and faster inspection of complex geometrical parts.