Railways

Non-destructive inspection of rail tracks and rolling stock is greatly increasing in significance due to growing amounts of rail traffic carrying heavier loads at higher speeds.

High external stresses on the rail superimposed with internal stresses can result in considerable load on rails and welding joints. Excessive load could extend existing flaws, potentially leading to rail fracture.

Monitoring of track and rolling stock integrity and detection of internal defects, cracks, or voids ensures continuous smooth operation of railroad transportation and plays a critical role in avoiding potentially catastrophic failures. ScanMaster offers a variety of fully automated ultrasonic inspection systems for identifying defects in rails and rolling stock during both part production and in-service inspection

Metro Rail Inspection

For efficient inspection of in-situ metro and underground railways, ScanMaster has developed the UT-M18. The UT-M18 pairs ScanMaster’s TrackMaster technology (based on the well-known SFB-100 model) with a self-propelled electric powered trolley. This combination provides a cost-effective testing solution for inspection in demanding and harsh environments.

The UT-M18, which utilizes the TrackMaster software package, provides real-time detection and recording of railway flaws; while generating comprehensive reports of inspection setups and collected data.

Railways

Non-destructive inspection of rail tracks and rolling stock is greatly increasing in significance due to growing amounts of rail traffic carrying heavier loads at higher speeds.

High external stresses on the rail superimposed with internal stresses can result in considerable load on rails and welding joints. Excessive load could extend existing flaws, potentially leading to rail fracture.

Monitoring of track and rolling stock integrity and detection of internal defects, cracks, or voids ensures continuous smooth operation of railroad transportation and plays a critical role in avoiding potentially catastrophic failures. ScanMaster offers a variety of fully automated ultrasonic inspection systems for identifying defects in rails and rolling stock during both part production and in-service inspection

Metro Rail Inspection

For efficient inspection of in-situ metro and underground railways, ScanMaster has developed the UT-M18. The UT-M18 pairs ScanMaster’s TrackMaster technology (based on the well-known SFB-100 model) with a self-propelled electric powered trolley. This combination provides a cost-effective testing solution for inspection in demanding and harsh environments.

The UT-M18, which utilizes the TrackMaster software package, provides real-time detection and recording of railway flaws; while generating comprehensive reports of inspection setups and collected data.

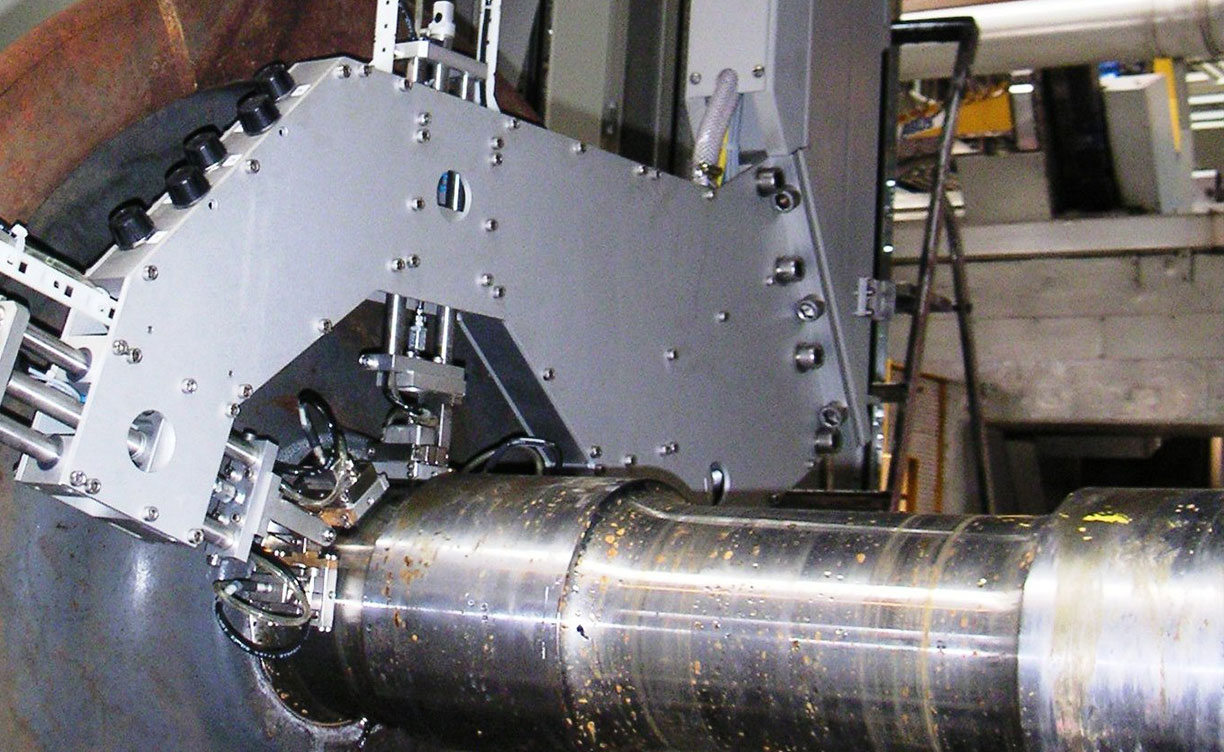

A variety of inspection systems are available for wheels, axles and combined wheel set assemblies and are designed for in-service, production line or repair shops. ScanMaster’s field proven systems enable fast scanning and provide accurate data acquisition. Inspection results are displayed and reported in standard or customized formats.

Axles and Wheels Inspection