UT/x Spot Weld Testing

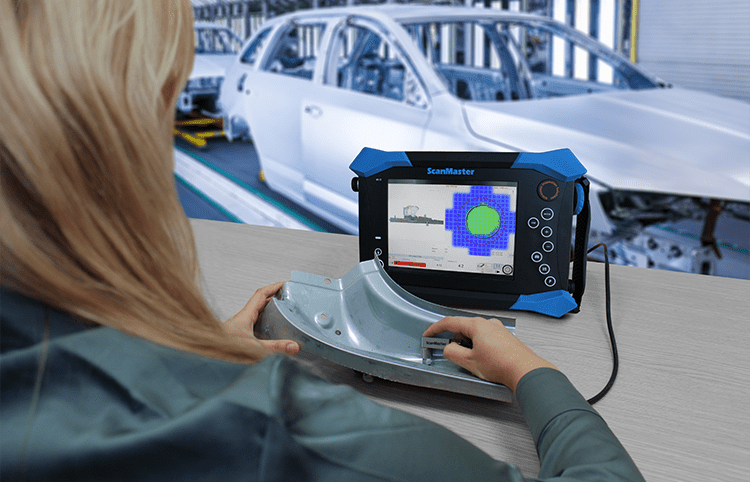

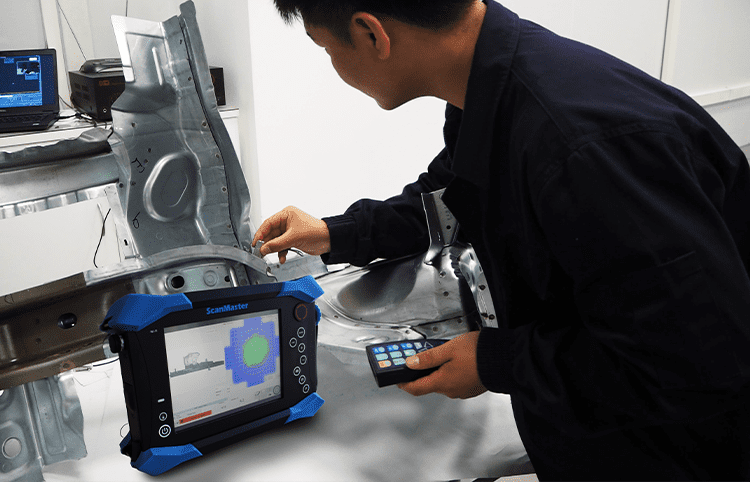

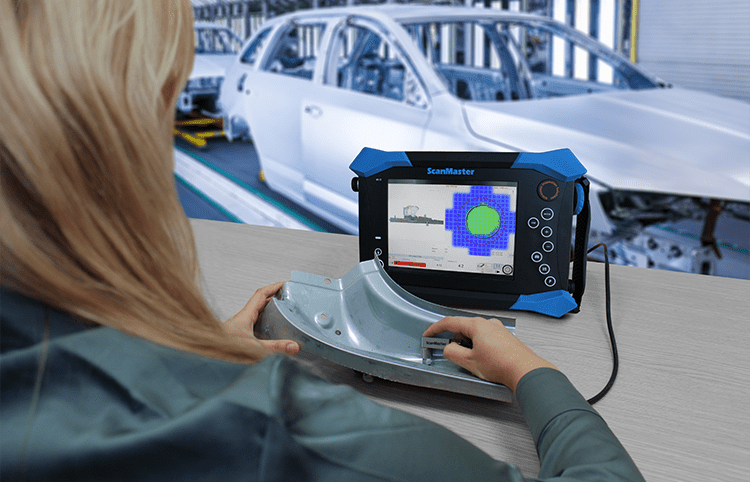

The ScanMaster UT/x is a new integrated rugged Phased-Array instrument for spot weld testing in industrial environments. The solution is a successor of the famous UT/Mate spot weld testing instrument.

Faster Testing

ScanMaster UT/x uses a 20 MHz detachable PA matrix transducer incorporating 209 separate virtual elements with a 1mm pitch for welds up to 9mm diameters, and a 10MHz probe with a 2mm pitch for welds up to 16mm diameters. It includes a built-in water path for ultimate UT performance and a flexible membrane to compensate for different weld indentations. The ScanMaster UT/x can also work with a hard delay line for faster testing on flat surfaces, such as aluminum welds. Its hot-swap battery enables continuous operation and extended mobility.

Comfortable View

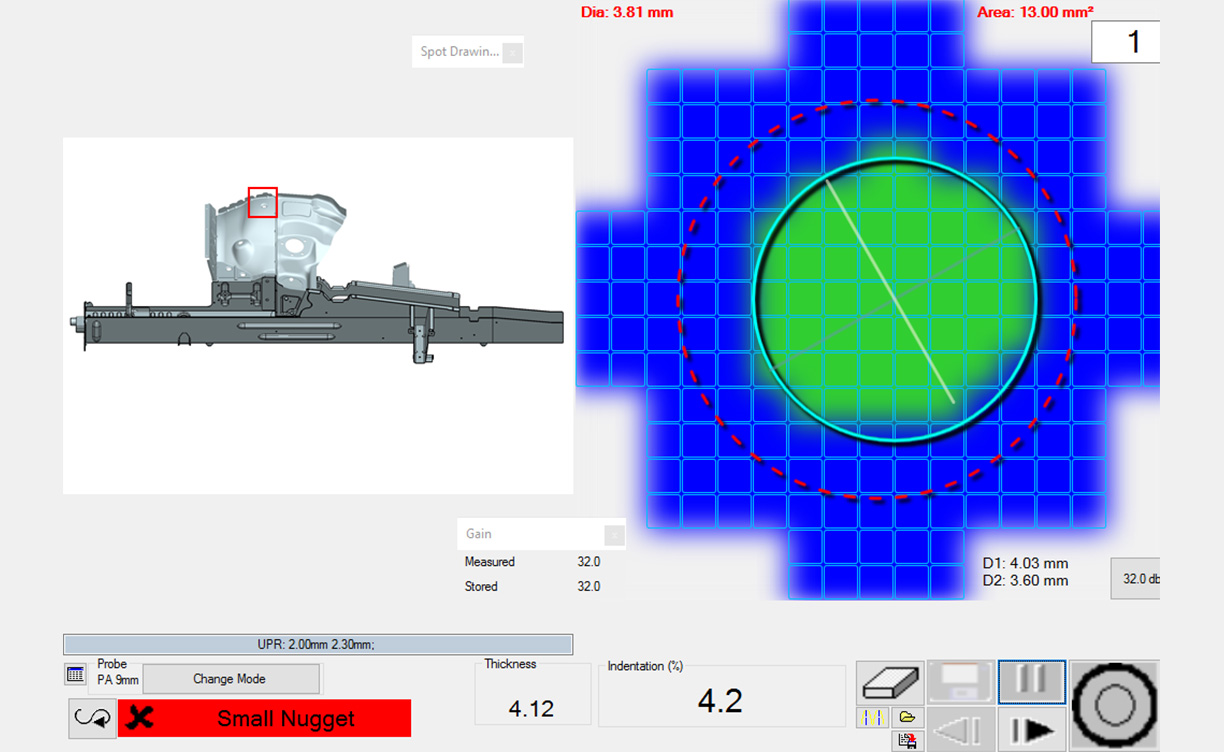

The UT/x main screen enables a comfortable view of the weld under inspection side by side with the part's drawing/photo. Clicking on a desired element on the matrix to the right will present the corresponding A-scan briefly on the left side of the screen where the part's drawing is located.

Other frequently-used controls are located in the bottom of the screen.

UT/x Spot Weld Testing

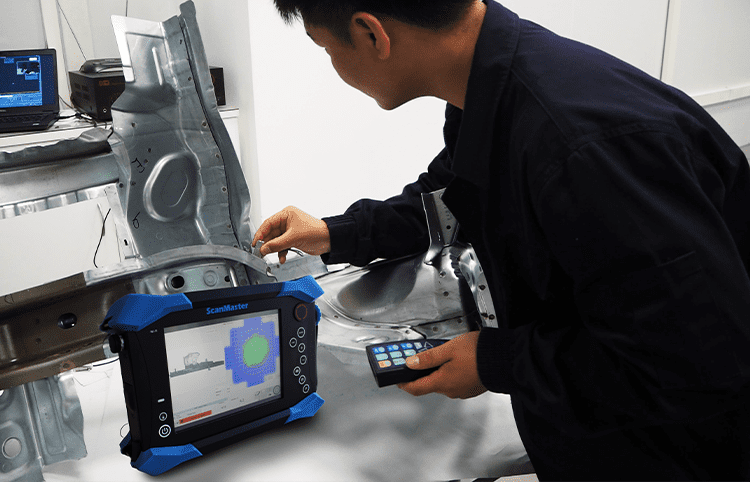

The ScanMaster UT/x is a new integrated rugged Phased-Array instrument for spot weld testing in industrial environments. The solution is a successor of the famous UT/Mate spot weld testing instrument.

Faster Testing

ScanMaster UT/x uses a 20 MHz PA matrix transducer incorporating 209 separate virtual elements with a 1mm pitch for welds up to 9mm diameters, and a 10MHz probe with a 2mm pitch for welds up to 16mm diameters. It includes a built-in water path for ultimate UT performance and a flexible membrane to compensate for different weld indentations. The ScanMaster UT/x can also work with a hard delay line for faster testing on flat surfaces, such as aluminum welds. Its hot-swap battery enables continuous operation and extended mobility.

Comfortable View

The UT/x main screen enables a comfortable view of the weld under inspection side by side with the part's drawing/photo. Clicking on a desired element on the matrix to the right will present the corresponding A-scan briefly on the left side of the screen where the part's drawing is located.

Other frequently-used controls are located in the bottom of the screen.

UT/x Features and Benefits

- Nugget size measurement

- Nugget area measurement

- Weld thickness measurement

- Advanced new technology for nugget quality classification

- Fast and reliable inspection

- Single-element probe and PA probe inspection using the same software and hardware platform

- Cable can be disconnected from the probe to enable fast cable replacement

- Efficient scan plan preparation

- Support for migration of existing ScanMaster plans

- Dual probe tip selection

- Accommodation of weld diameters up to 16mm

- Utilization of ScanMaster’s patent-registered unique technology

UT/x Features and Benefits

- Nugget size measurement

- Nugget area measurement

- Weld thickness measurement

- Advanced new technology for nugget quality classification

- Fast and reliable inspection

- Single-element probe and PA probe inspection using the same software and hardware platform

- Efficient scan plan preparation

- Support for migration of existing ScanMaster plans

- Dual probe tip selection

- Accommodation of weld diameters up to 16mm

- Utilization of ScanMaster’s patent-registered unique technology

Want to know more?

Download now the UT/x Brochure >>>