Ultrasonic Spot Weld Testing

The principal use of resistance spot welding is to join overlapping sheets of metal when the joint does not need to be gas-tight or liquid-tight. Since separate fasteners are not required for this process, fabrication is economical and fast. Spot welding is used for fabrication of numerous metal sheet products, such as automotive bodies, appliances, enclosures, and furniture.

The average car contains several thousand spot welds that are essential to its structural integrity. To remain competitive, the automotive industry requires a spot weld testing solution that facilitates increased production volumes while maintaining the highest quality standards.

Highly effective ultrasonic inspection methods not only meet these requirements, but also detect symptoms of a deteriorating welding process, providing quasi-real-time feedback for immediate corrective actions. Detecting and addressing issues before they become critical helps efficiently maintain optimum welding conditions by preventing faulty weld batches and production line interruptions.

This is where ScanMaster’s Spot Weld testing instruments come in.

Developed through close coordination with the automotive industry, ScanMaster’s Spot Weld ultrasonic testing instruments have set new standards in the field, significantly reducing inspection time while delivering a quick return on investment.

Hundreds of these Spot Weld testing instruments are currently being used by car manufacturers, whose feedback is a valuable source for continued enhancement of equipment performance.

Ultrasonic Spot Weld Testing

UT/Mate - Spot Weld Inspector

ScanMaster's most widely-used conventional UT (ultrasonic) instrument for spot weld testing can easily convert any PC or laptop to a fully automated spot weld classification instrument, with field-proven reliability as a high-end solution for the automotive body shop.

The internationally marketed UT/Mate is used by the majority of globally leading car manufacturers and remains a top selection for conventional UT instruments.

UT/x - Spot Weld Inspection

The UT/x is ScanMaster’s Phased-Array instrument for reliable spot weld testing in the automotive production line and in laboratories. This fully automated classification instrument brings an intuitive UT inspection experience to the next level, allowing professional testing and reporting by any minimally trained operator. The extremely quick inspection, lasting only a few seconds, provides a clear map of the weld, including characteristics such as diameter and area that can be presented and stored for later reporting.

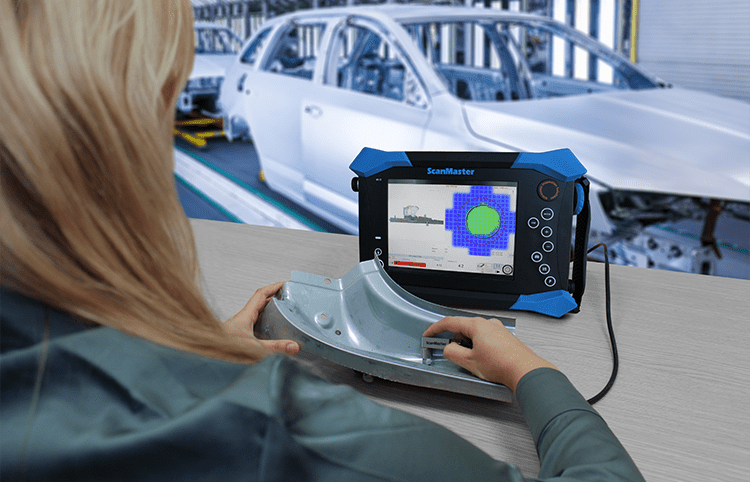

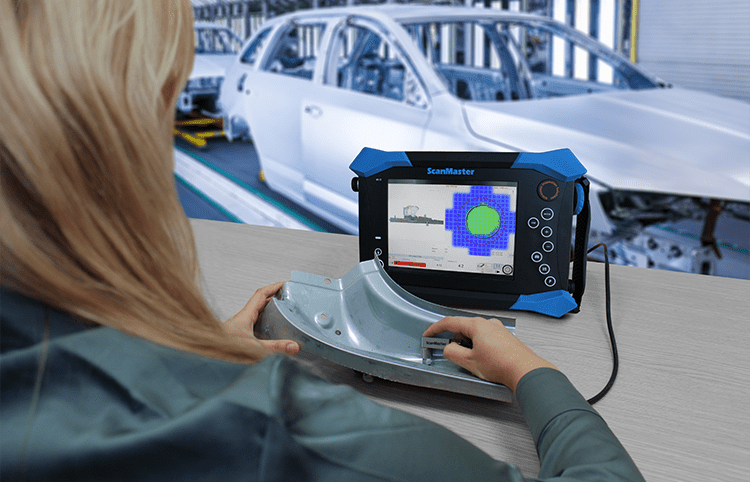

UT/Pro V2 - Integrated Spot Weld Inspector

The UT/Pro V2 combines all the advantages of the UT/Mate into a complete solution for the automotive product line. Its military-class tablet enables seamless operation under harsh conditions, utilizing all the advantages of the touch screen interface in highly intuitive ways.

The long-lasting battery and integrated handle allow for extended continuous use and smooth mobility throughout the plant.

Spot Weld Testing: Applications

UT/Mate - Spot Weld Inspector

ScanMaster's most widely-used conventional UT instrument for spot weld testing can easily convert any PC or laptop to a fully automated spot weld classification instrument, with field-proven reliability as a high-end solution for the automotive body shop.

The internationally marketed UT/Mate is used by the majority of globally leading car manufacturers and remains a top selection for conventional UT instruments.

UT/x - Spot Weld Inspection

The UT/x is ScanMaster’s Phased-Array instrument for reliable spot weld testing in the automotive production line and in laboratories. This fully automated classification instrument brings an intuitive UT inspection experience to the next level, allowing professional testing and reporting by any minimally trained operator.

The extremely quick inspection, lasting only a few seconds, provides a clear map of the weld, including characteristics such as diameter and area that can be presented and stored for later reporting.

UT/Pro V2 - Integrated Spot Weld Inspector

The UT/Pro V2 combines all the advantages of the UT/Mate into a complete solution for the automotive product line. Its military-class tablet enables seamless operation under harsh conditions, utilizing all the advantages of the touch screen interface in highly intuitive ways.

The long-lasting battery and integrated handle allow for extended continuous use and smooth mobility throughout the plant.

What is Ultrasonic Spot Weld Testing?

The ultrasonic method for spot weld testing is based on the detection of multiple reflections from the backwall of the welded structure, together with intermediate echoes generated by the interface between plates or by flaws in the nugget. The total length of the echo sequence from its total thickness, together with the signal attenuation (rate of decay or amplitude drop) and the amplitude and position of the intermediate echoes differentiates between good spot welds and defective ones.

The UT method was developed in the early 1960s, using analog instruments. When using such instruments, operators had to visually examine each signal and make decisions on a complex screen display. These factors made the method difficult to interpret, unreliable and impractical.

The advent of digital ultrasonic instruments provided the possibility of computer-assisted decision-making with online UT signal analysis. The UT method has been adopted in the car industry as the most appropriate method for spot weld inspection, both in the production line and in the lab.

The main advantages of the UT method include, in addition to its non-destructive quality, high throughput, high reliability of detection, and full documentation capability.