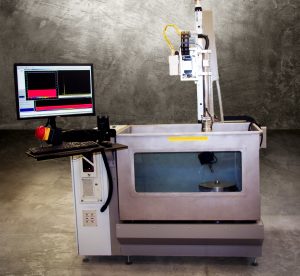

ScanMaster’s LS-50 immersion scanner series

ScanMaster Systems is pleased to introduce the LS-50 immersion scanner series, suitable for manufacturing sites, metallurgical labs and research institutes.

The LS-50 is an ideal solution for inspection of discs, bearings, bars, metallurgical samples, monolithic composites and more.

Although compact, LS-50 scanners are fully integrated systems that contain UT electronics, mechanics, motion control and software, all designed, manufactured and integrated by ScanMaster.

The LS-50 includes all the standard features of the CSI application, ScanMaster’s well-known inspection software package.

LS-50 immersion scanners can support both turntable and bar rotator configurations.

The LS-50TT

Includes a turntable with chucks for inspection of rotational geometry parts, such as discs, bearings, etc.

The system can support parts of up to 80kg (176Ib), with diameters of up to 400mm (16”).

A yoke for through-transmission inspection can be provided.

The LS-50BR

Includes a rotator for inspection of bars and tubes. The scanner can support parts of up to 500 mm (20″) in length with diameters of 25-120mm (1″-5″).

The system complies with inspection standards such as AMS-STD-2154 as well as the SEP 1927 inspection method.

A servo-driven A/B manipulator or a probe holder with manual probe angulation can be provided for either configuration.

Bar rotator with probe holder A/B manipulator with yoke

Double the productivity, half the expenditure!

This pair of ScanMaster’s compact LS-50 scanning systems, improve efficiency, increase productivity and can be run by a single operator.

Interface to loading/unloading robot for automation of inspection.