Multi-Zone Ultrasonic Inspection of Bars

Multi-zone inspection of titanium using ultrasound involves dividing the material into distinct regions and scanning each with a zone-specific probe to detect internal flaws. This non-destructive method identifies cracks, voids, and inclusions, ensuring the material’s integrity and quality. Essential for aerospace and medical applications, ultrasonic inspection provides precise and reliable results, meeting stringent industry standards.

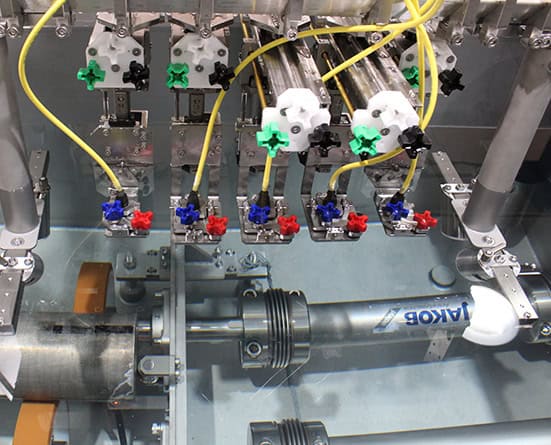

ScanMaster Systems has developed a line of bar inspection systems that include an immersion tank, part rotator (bar rotator), independent calibration bar rotator (if required), and XYZ scanner featuring innovative probe heads.

These systems enable multi-zone inspection according to standards like AMS 2628 and DMC0022 (Snecma). The scanner can hold two multi-probe heads, each equipped with bar-following modules. The probe holders can accommodate various types of probes and allow for their adjustment in multiple directions.

An A/B manipulator can also be added to the system as part of the head or on a separate bridge, enlarging the scanner capabilities.

This comprehensive setup ensures thorough and accurate inspection of bars and shafts.