The New Generation of DS-200i

ScanMaster is pleased to introduce the new generation of DS-200i inspection systems.

The new generation of DS-200i scanners provide a cost-effective C-scan inspection solution with a superior design. These fully integrated systems include ultrasonic electronics, scanning mechanics, axes motion control, data acquisition and processing software.

Typical applications for the DS-200i include:

- Large discs and spools of aero-engines such as the GE90, GEnX, RR Trent 1000 and others

- Rings of large bearing such as wind turbine pitch bearings

- Flat or complex non-rotational parts

The new DS-200i is available in two standard sizes, as specified below. Alternate dimensions can be provided upon request

| DS-200 Series | X mm(inch) | Y mm (inch) | Z mm (inch) | Max. Part Diameter mm (inch) |

Turntable Capacity kg (lbs) |

| DS-200i-1800 | 2,000 (78) | 1,500 (59) | 1,300 (51) | 1,800 (70) | 1,500 (3,300) |

| DS-200i-2000 | 2,000 (78) | 1,800 (70) | 1,300 (51) | 2,000 (78) | 2,000 (4,400) |

Meet The DS-200i

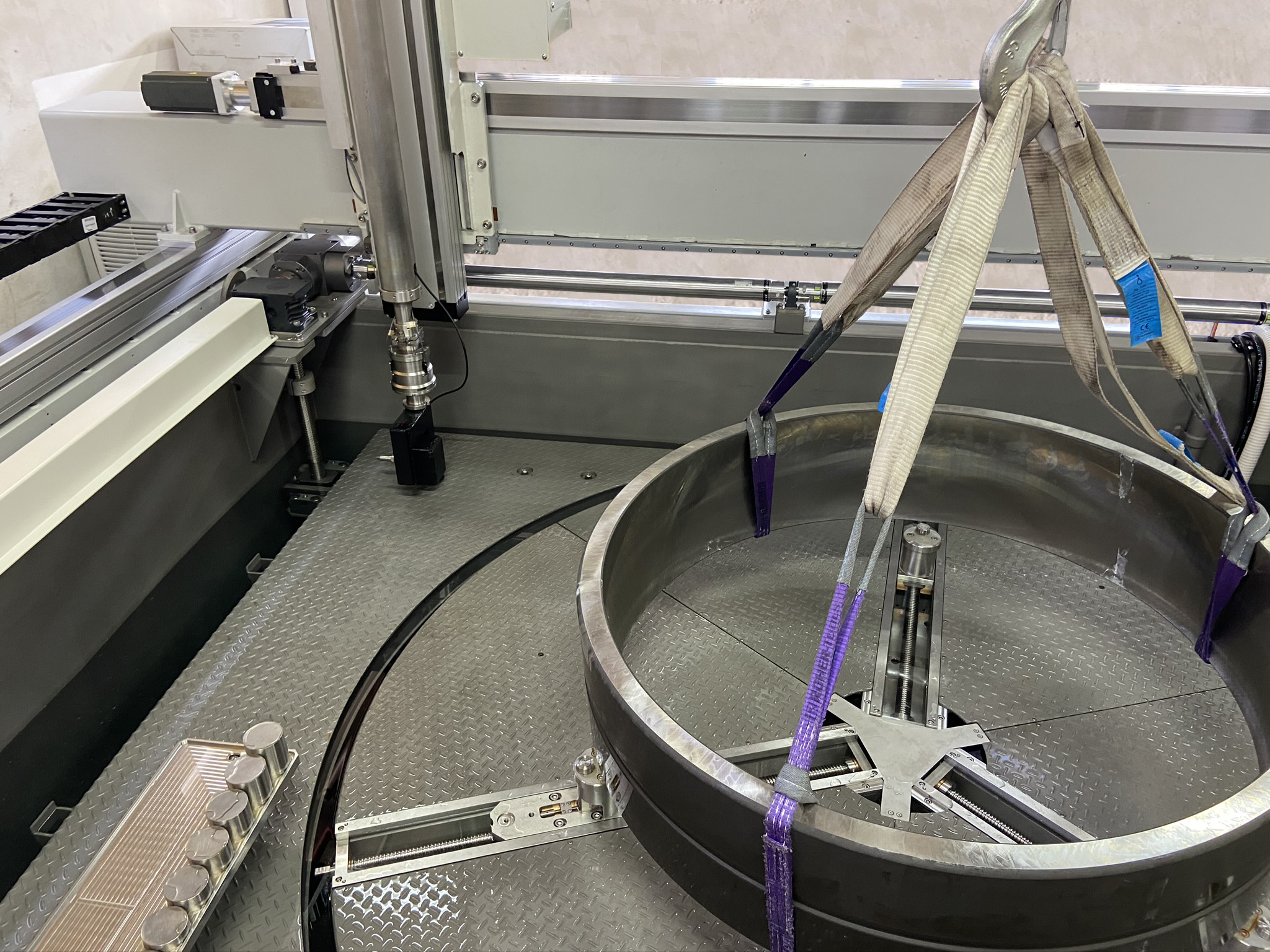

As with all ScanMaster scanners, the tank is separate from the gantry, which encompasses the tank from two sides and the back only. The X axis is driven along the bridge beam, which is positioned over the Y axis motion on both sides of the tank. This configuration ensures a clear view of the tank and provides the operator and part loader with easy and safe access to the front of the tank.

All linear axes are made up of high precision modules with sliding covers to prevent accumulation of dust and other particles.

The system utilizes ScanMaster’s standard dual-gimbal probe manipulator with it’s SafeGuard anti-collision fuse.

High-speed action jacks enable the lifting platform to reach speeds of up to 25 mm/sec.

The following optional features can be delivered with the turntable:

- Motorized chucks

- Anti-slippage covers

The DS-200i can be installed in either of these foundation configurations:

- Tank on floor – In this configuration the customer provides a platform with stairs on which the operator table is located. This option is less expensive but has an impact on convenience of system operation.

- Tank in pit (gantry remains floor mounted) – This configuration requires a pit to be constructed in the factory ground, but provides more convenience and a safer environment for system operation and part loading/unloading.

Tank on floor configuration Tank in pit configuration