UT/x Spot Weld Testing

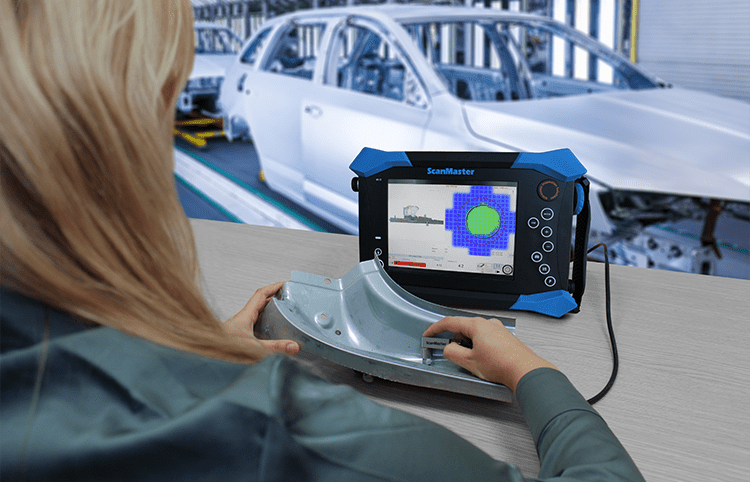

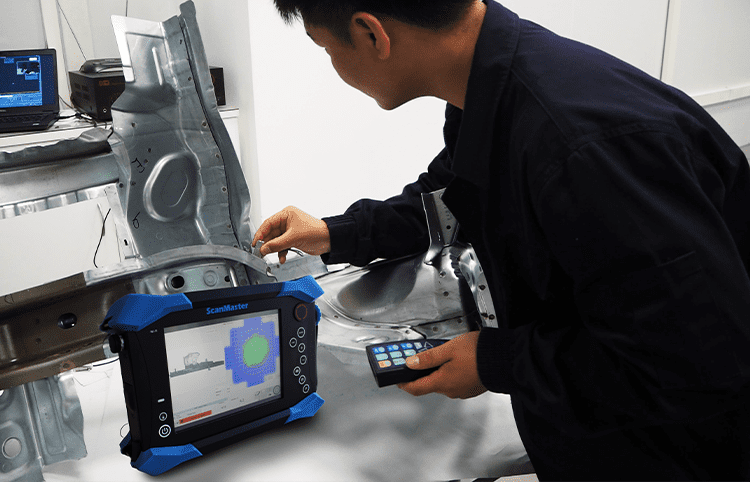

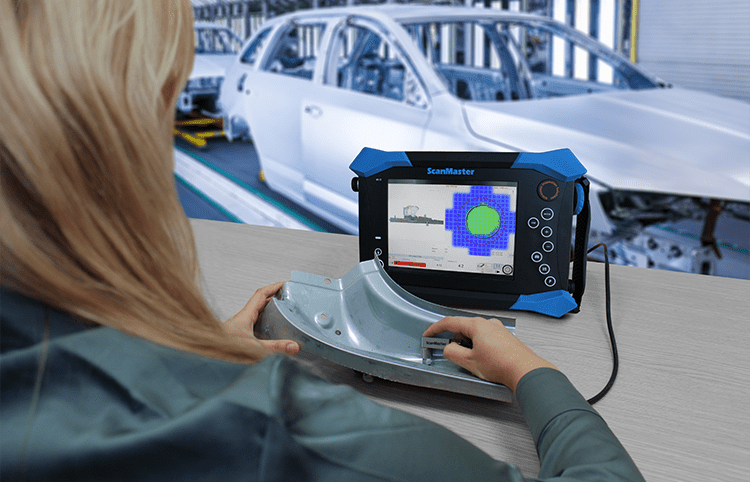

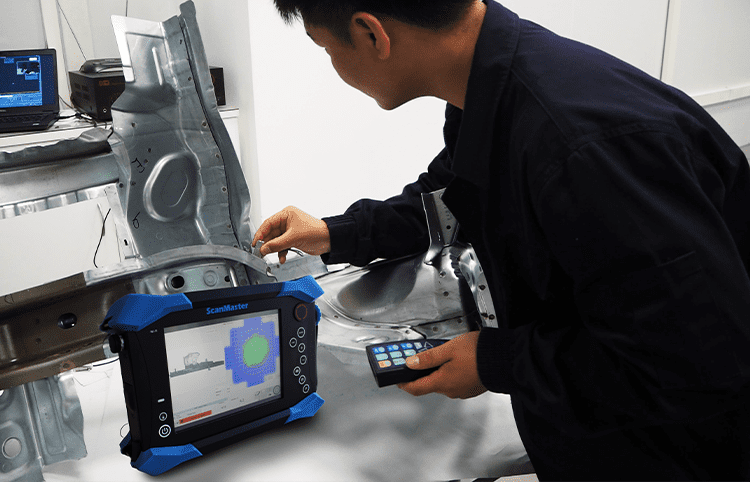

The ScanMaster UT/x is a new integrated rugged Phased-Array instrument for spot weld testing in industrial environments. The solution is a successor of the famous UT/Mate spot weld testing instrument.

Faster Testing

ScanMaster UT/x employs advanced phased array transducer technology optimized for inspecting a wide range of weld sizes, ensuring precise detection and evaluation of weld integrity.

It includes a built-in water path for ultimate UT performance and a flexible membrane to compensate for different weld indentations. The ScanMaster UT/x can also work with a hard delay line for faster testing on flat surfaces, such as aluminum welds. Its hot-swap battery enables continuous operation and extended mobility.

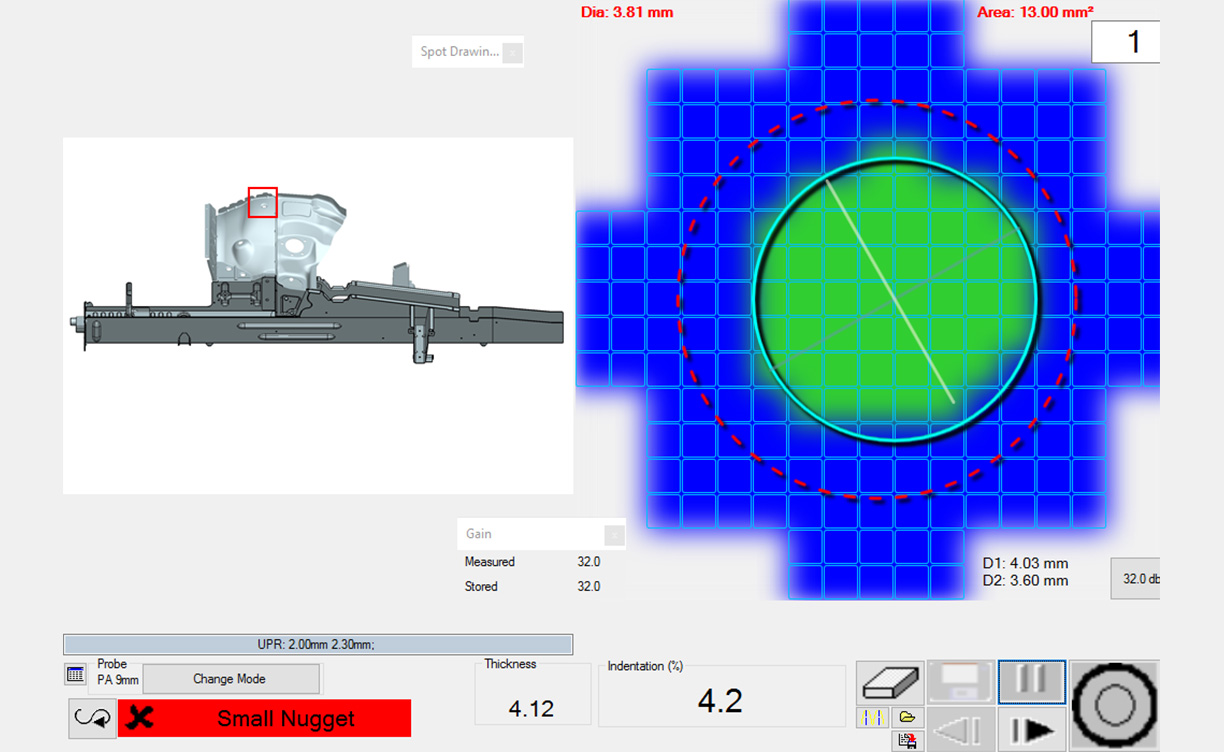

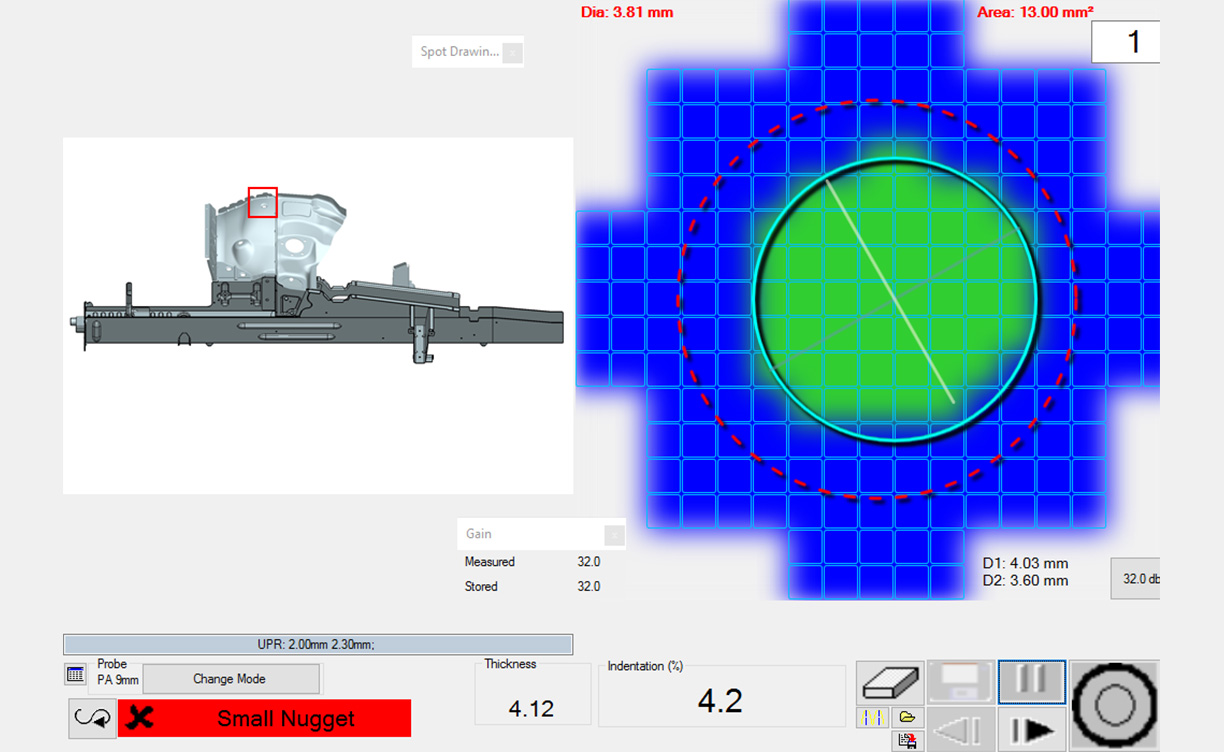

Comfortable View

The UT/x main screen enables a comfortable view of the weld under inspection side by side with the part's drawing/photo. Clicking on a desired element on the matrix to the right will present the corresponding A-scan briefly on the left side of the screen where the part's drawing is located.

Other frequently-used controls are located in the bottom of the screen.

UT/x Spot Weld Testing

The ScanMaster UT/x is a new integrated rugged Phased-Array instrument for spot weld testing in industrial environments. The solution is a successor of the famous UT/Mate spot weld testing instrument.

Faster Testing

ScanMaster UT/x employs advanced phased array transducer technology optimized for inspecting a wide range of weld sizes, ensuring precise detection and evaluation of weld integrity.

It includes a built-in water path for ultimate UT performance and a flexible membrane to compensate for different weld indentations. The ScanMaster UT/x can also work with a hard delay line for faster testing on flat surfaces, such as aluminum welds. Its hot-swap battery enables continuous operation and extended mobility.

Comfortable View

The UT/x main screen enables a comfortable view of the weld under inspection side by side with the part's drawing/photo. Clicking on a desired element on the matrix to the right will present the corresponding A-scan briefly on the left side of the screen where the part's drawing is located.

Other frequently-used controls are located in the bottom of the screen.

UT/x Features and Benefits

- Nugget size measurement

- Nugget area measurement

- Weld thickness measurement

- Advanced new technology for nugget quality classification

- Fast and reliable inspection

- Single-element probe and PA probe inspection using the same software and hardware platform

- Cable can be disconnected from the probe to enable fast cable replacement

- Efficient scan plan preparation

- Support for migration of existing ScanMaster plans

- Dual probe tip selection

- Accommodation of weld diameters up to 16mm

- Utilization of ScanMaster’s patent-registered unique technology

UT/x Features and Benefits

- Nugget size measurement

- Nugget area measurement

- Weld thickness measurement

- Advanced new technology for nugget quality classification

- Fast and reliable inspection

- Single-element probe and PA probe inspection using the same software and hardware platform

- Efficient scan plan preparation

- Support for migration of existing ScanMaster plans

- Dual probe tip selection

- Accommodation of weld diameters up to 16mm

- Utilization of ScanMaster’s patent-registered unique technology

How ultrasonic phased array testing can help with spot weld detection in the automotive industry

Ultrasonic phased array testing (PAUT) is a non-destructive testing (NDT) method that utilizes sound waves to inspect materials for defects. In the automotive industry, PAUT is particularly valuable for assessing the quality of spot welds.

- How it works: PAUT employs an array of transducers to generate and receive ultrasonic waves. By precisely controlling the timing and amplitude of the signals emitted from each transducer element, the technician can focus the sound beam and steer it within the material. This enables the inspection of complex geometries, such as spot welds, from various angles.

- Benefits for spot weld detection:

1. Improved accuracy: PAUT provides high-resolution images of the weld, allowing for precise detection of defects like cracks, voids, and lack of fusion.

2. Faster inspection: The ability to read lager areas with automated probe perpendicularity reduces inspection time in the production line.

3. Reduced costs: Faster inspections and improved defect detection can lead to reduced repair costs and improved production efficiency.

4. Enhanced safety: By identifying potential failures before they occur, PAUT helps to improve the safety and reliability of automotive components.

Want to know more?

Download now the UT/x Brochure >>>