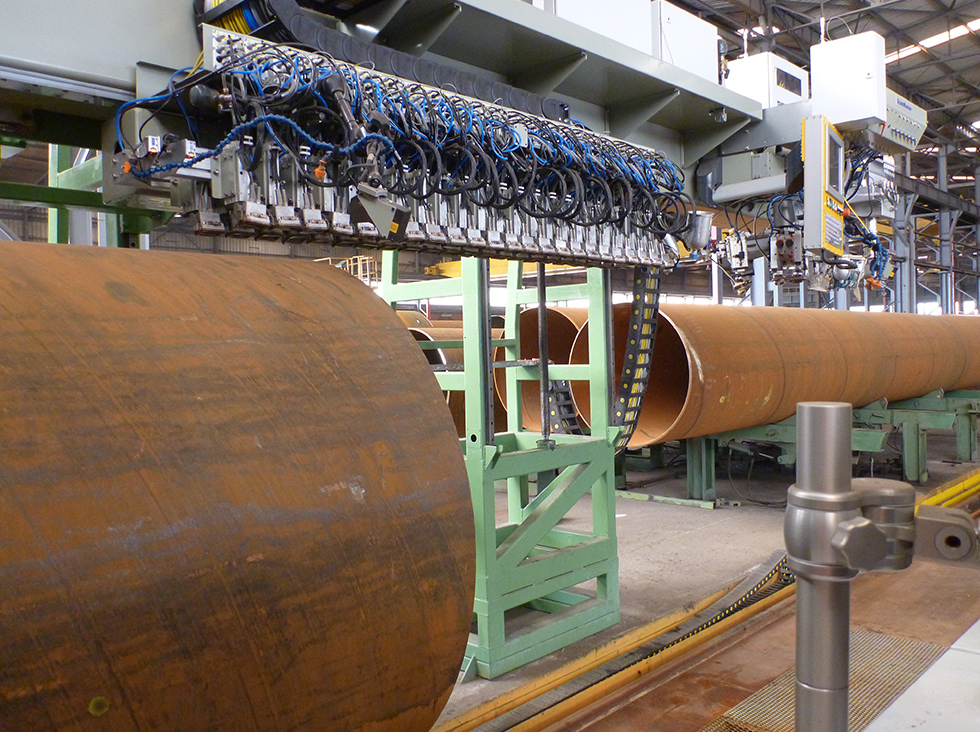

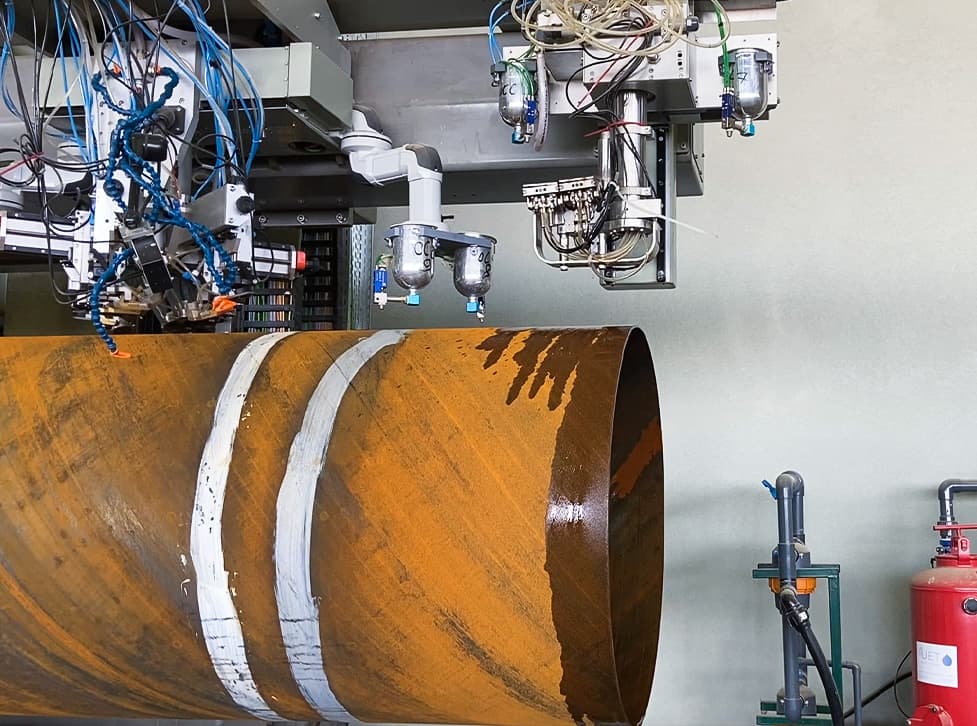

Spiral SAW Pipe Inspection Systems

The AS-200S Systems are designed to inspect Spiral Submerged Arc Welded (H-SAW) Pipes, including the strip, weld, pipe body and Heat Affected Zone (HAZ). The systems may be integrated as strip inspection, online inspection right after the welding process and offline inspection as a final pipe test, and can be set up using a variety of ultrasonic configurations, according to the specific inspection requirements.

Both static and moving inspection head configurations are available for the offline pipes inspection, to accommodate different site conditions and throughput requirements.

Spiral SAW Pipe Inspection Systems

The AS-200S Systems are designed to inspect Spiral Submerged Arc Welded (H-SAW) Pipes, including the strip, weld, pipe body and Heat Affected Zone (HAZ). The systems may be integrated as strip inspection, online inspection right after the welding process and offline inspection as a final pipe test, and can be set up using a variety of ultrasonic configurations, according to the specific inspection requirements.

Both static and moving inspection head configurations are available for the offline pipes inspection, to accommodate different site conditions and throughput requirements.

Spiral SAW Pipe: Systems Gallery

Adherence to common industry standards

- API 5L/ISO 3183

- Shell DEP-31.40.20.37-Gen.

- Chevron

- other pipeline requirements

Features and Benefits

- Modular inspection heads supporting different ultrasonic configurations

- Ability to inspect 100% of the body pipe after pipe forming

- Pipe end inspection modules

- Compact system design for efficient integration into existing lines

- Automated seam tracking using laser

- Ease of operation for quick setup and calibration

- On-site operator console

- Automated custom tailored inspection report for endless and cut pipes

- Robust - vibration free mechanical structure

- Unique ultrasonic transducers with internal coupling verification

- RFI shielding and ultrasonic instrument layout specifically designed for enhanced SNR

- Low maintenance and long lifespan