Special Pipes

Special Pipes

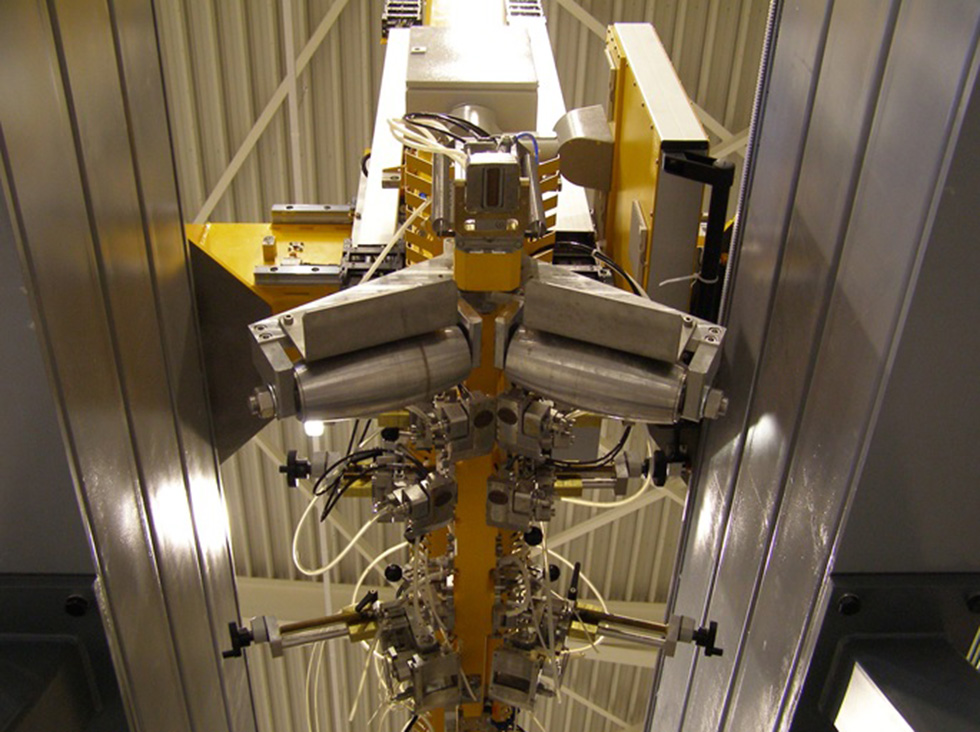

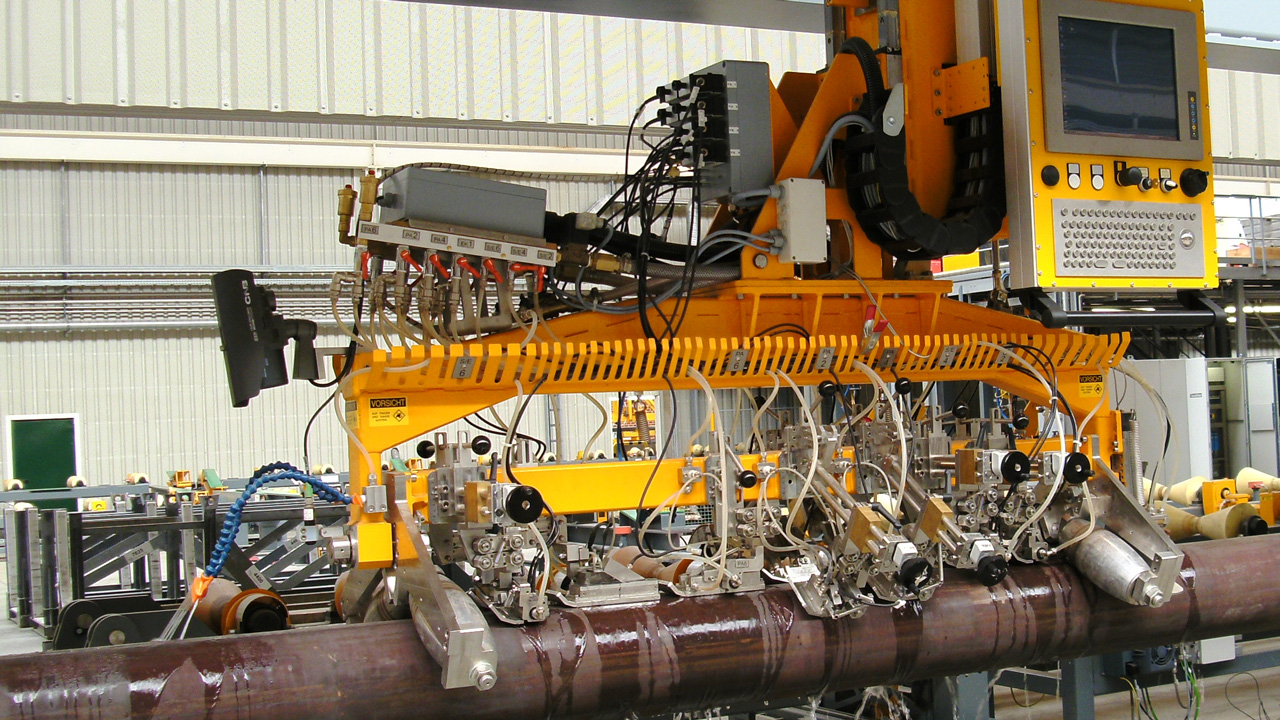

Phased Array Scanner for Inspection of Pipes

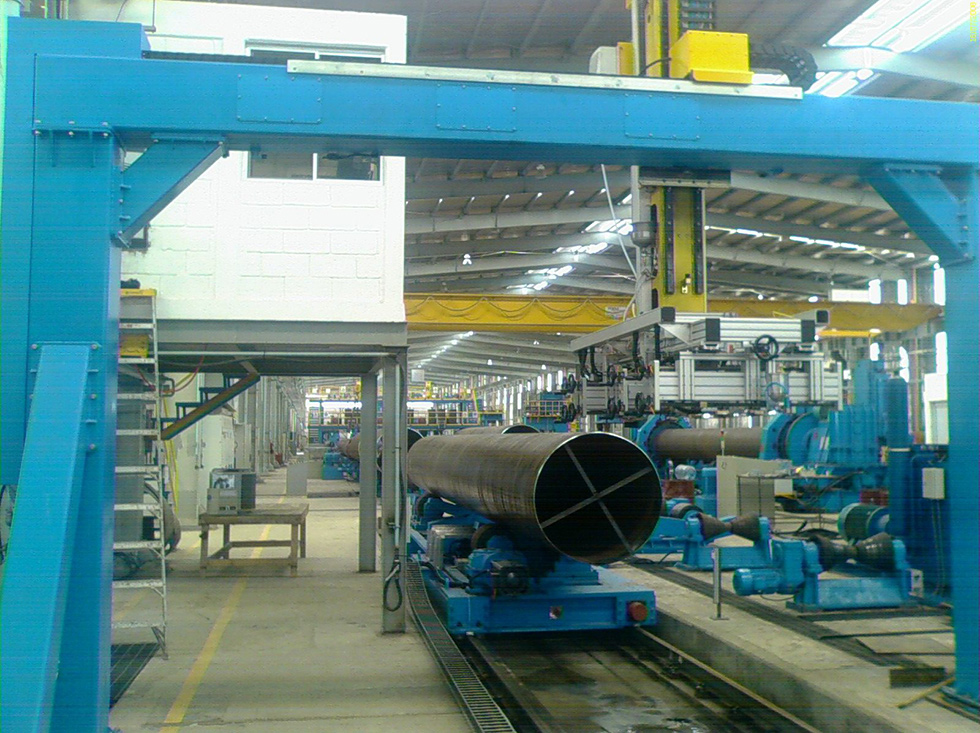

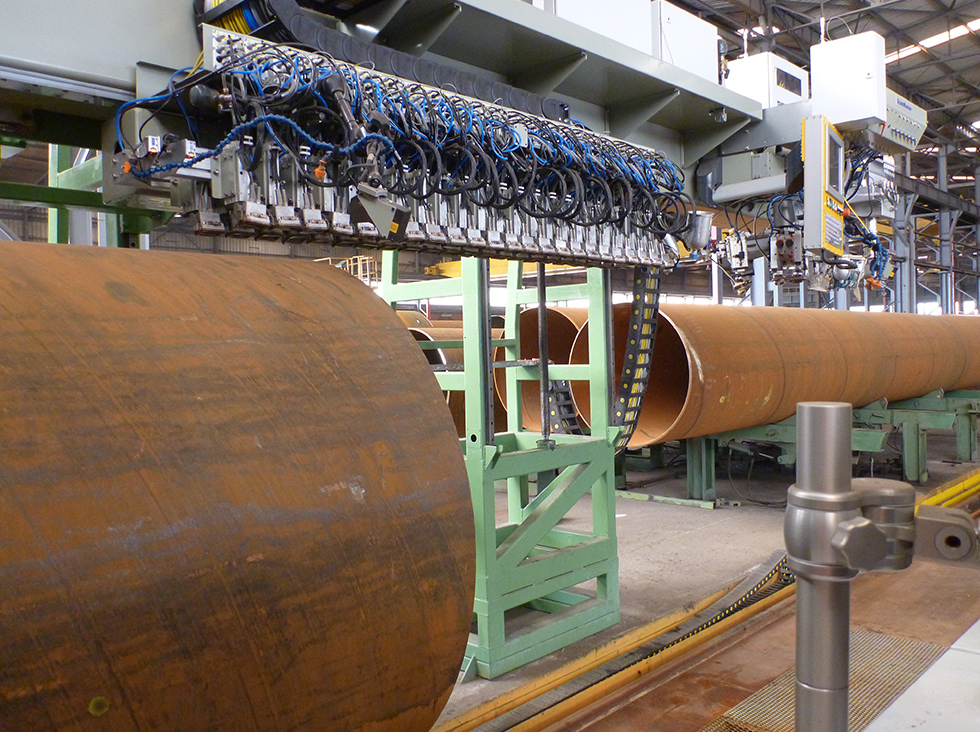

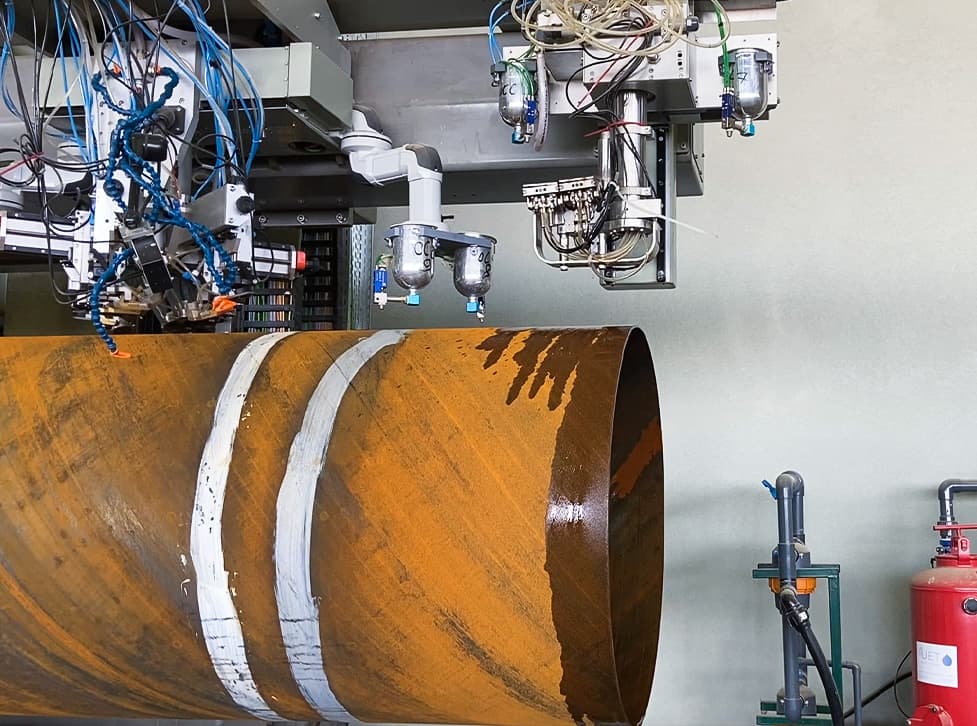

The AS-200S Systems are designed to inspect Spiral Submerged Arc Welded (H-SAW) Pipes, including the strip, weld, pipe body and Heat Affected Zone (HAZ). The systems may be integrated as strip inspection, online inspection right after the welding process and offline inspection as a final pipe test, and can be set up using a variety of ultrasonic configurations, according to the specific inspection requirements.

Both static and moving inspection head configurations are available for the offline pipes inspection, to accommodate different site conditions and throughput requirements.

Special Pipes

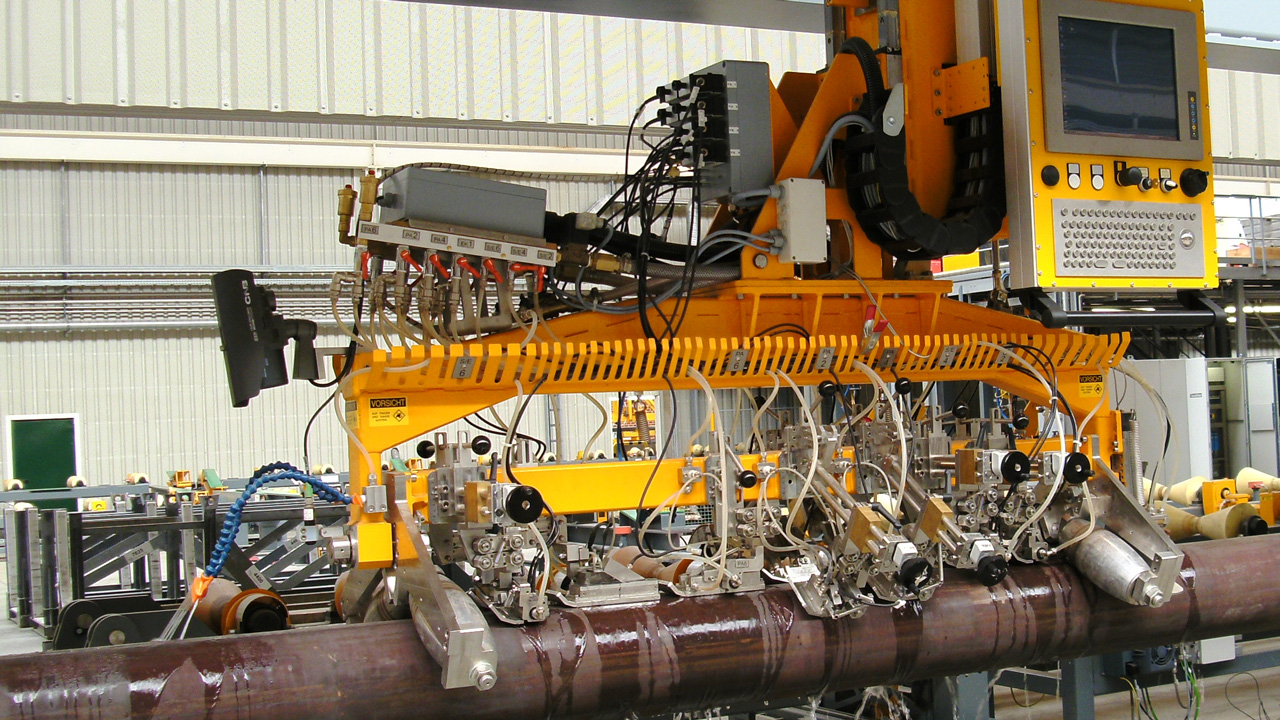

Phased Array Scanner for Inspection of Pipes

The AS-200S Systems are designed to inspect Spiral Submerged Arc Welded (H-SAW) Pipes, including the strip, weld, pipe body and Heat Affected Zone (HAZ). The systems may be integrated as strip inspection, online inspection right after the welding process and offline inspection as a final pipe test, and can be set up using a variety of ultrasonic configurations, according to the specific inspection requirements.

Both static and moving inspection head configurations are available for the offline pipes inspection, to accommodate different site conditions and throughput requirements.